Electroweld industries is a leading manufacturer of resistance welding equipment, serving the industry for over 45 years. Our welding machines are designed to provide a production solution at an affordable price while ensuring reliability and low cost maintenance.

Brand New Electroweld Pneumatically Operated Ring Butt Welder 100kva (rngw-100pn) Unlock 80% Savings [XelsjczL]

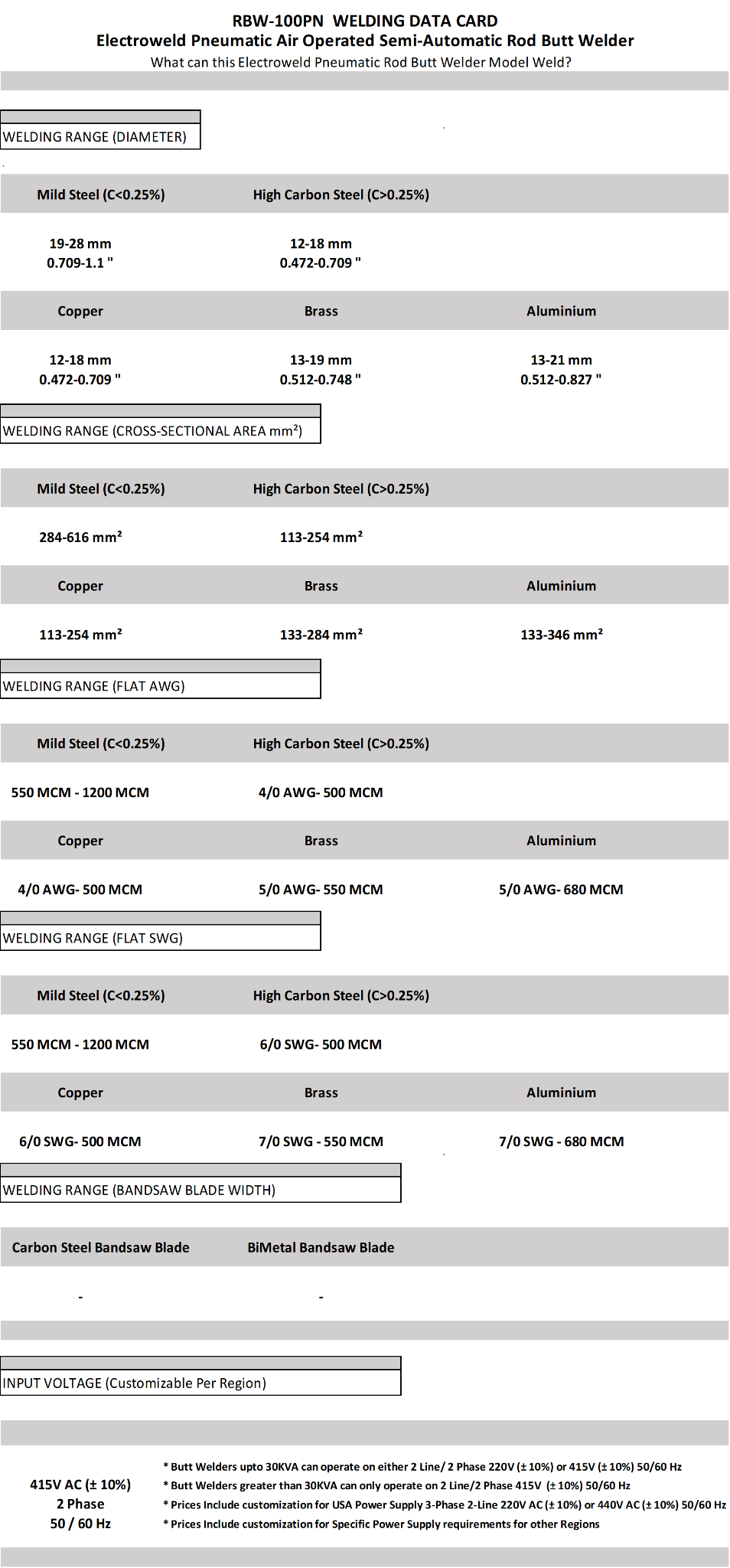

Weldability - Mild Steel: 19mm-28mm, High Carbon Steel: 12mm-18mm, Copper: 12mm-18mm, Brass: 13mm-19mm, Aluminium: 13mm-21mm.

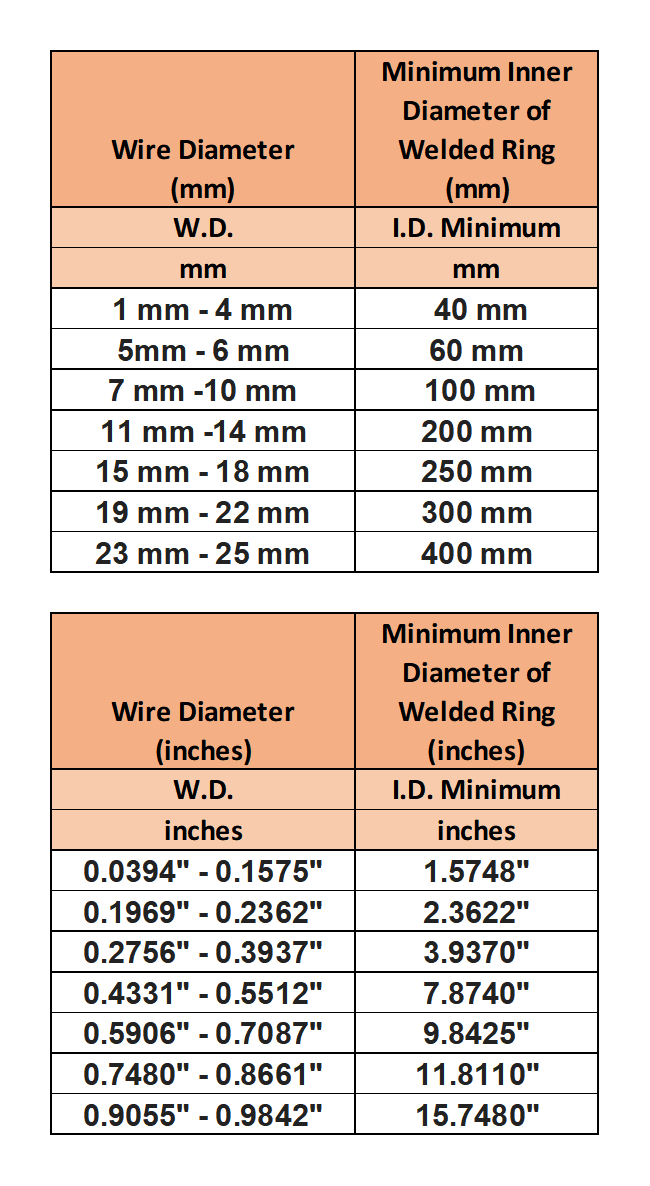

Minimum Required Inner Diameter's of Butt Welded Wire Ring Corresponding to the Wire Diameter:

For the Rings to be butt welded on Electroweld Butt Welders - following are the minimum required Inner Diameters of the Welded Rings.

Applications for Ring Butt Welding

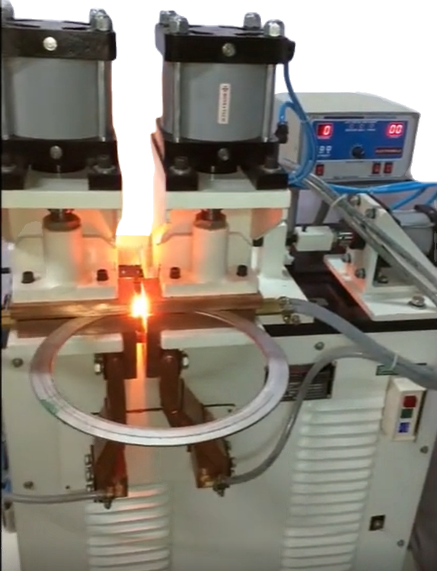

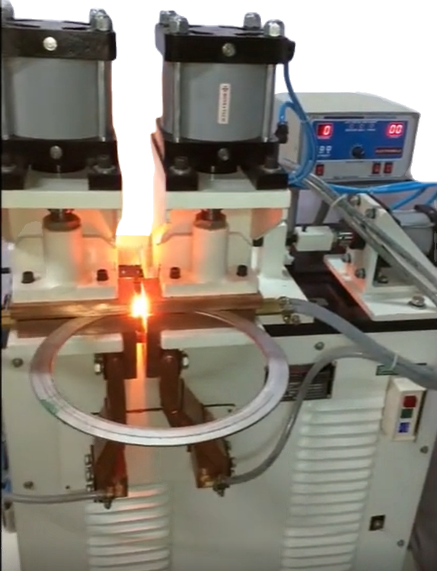

Butt Welding (a.k.a Upset Welding) can be used in the manufacturing of circular objects that have ends of the same size. This includes wire rings, tubular rings, burner rings, wheel rims, and more.Welded rings are typically used in air springs, burners, heaters, driers, air suspension systems, and steering wheels, though there are many more areas where wire rings are used. The Electroweld Ring Butt Welder supports Upset butt welding of all profiles of wires and flats of iron, steel, alloy and carbon steel, copper, aluminium, brass and other light metals and their alloys.

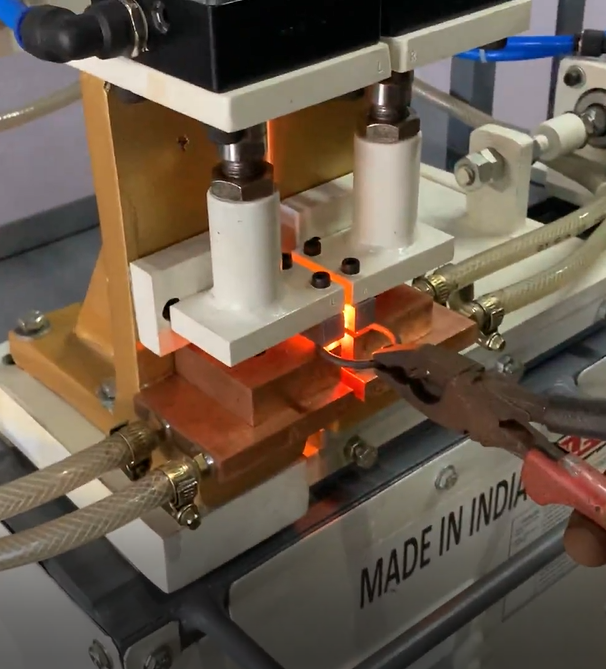

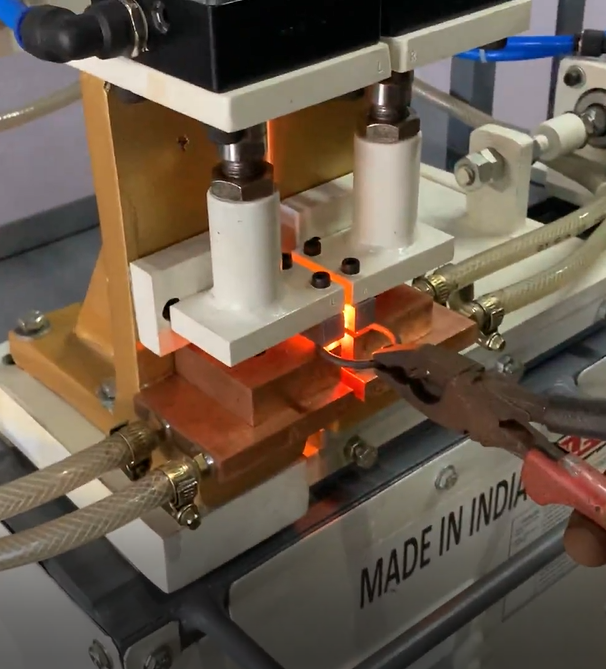

Wire Ring Butt Welding

Wire rings are solid metal wire that curved into a ring and welded together. These rings are made from steel or stainless steel and come in a variety of sizes. Small welded wire rings are made from 2-5mm wire and can have diameters as big as 30in. These smaller rings are typically found in air springs, filter and bag houses, and more. Large welded wire rings use 5-26mm wire and can have diameters as big as 40in. Types Wire Rings which can be welded with the Electroweld Butt Welder - steel rings for air spring and suspension systems, Resistance Welded Rings, Welded Hoops, Steel Hoops, etc. In addition to the uses above, the Electroweld Ring Butt Welder can weld large rings used in commercial fishing traps, construction piers, steering rims, and more.

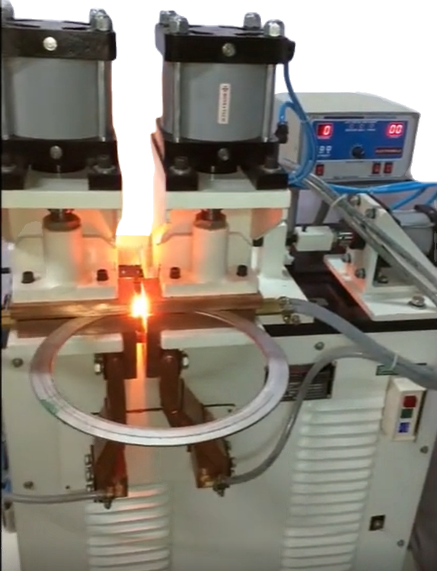

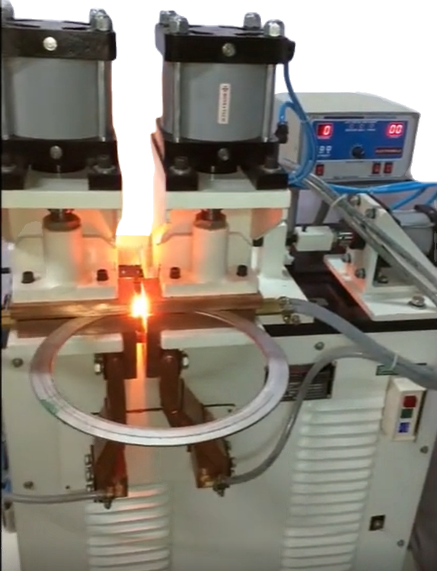

Tubular and Burner Rings Butt Welding

Tubular rings are made using butt welding to provide maximum strength and quality. The size of the ring tube ranges from 7mm – 60mm. Tubular rings are most commonly used in steering wheels. Burner rings are made from either carbon steel or stainless steel, depending on needs and burning temps. Burner rings are designed to work in heating equipment, used for industrial drying machines, chemical processing, crop dryers, nut dryers, large gas heaters and more.

Users: Include wire strip and rod drawing mills, transformer motor and switch gear manufacturers, hoop and ring manufacturers, wire forming industries, cable industries, automobile industries, air-conditioner and refrigerator makers, office equipment makers, etc.

Construction: The machines are constructed with a sturdy light alloy housing and designed as portable models mounted on a moveable chassis fitted with four wheels. They are constructed for quick, easy, and fool-proof operation, the welding process being automatic. Settings are simple, finely adjustable, and reproducible for all variables. Uniform welds of high strength capable of withstanding subsequent drawing ensured.

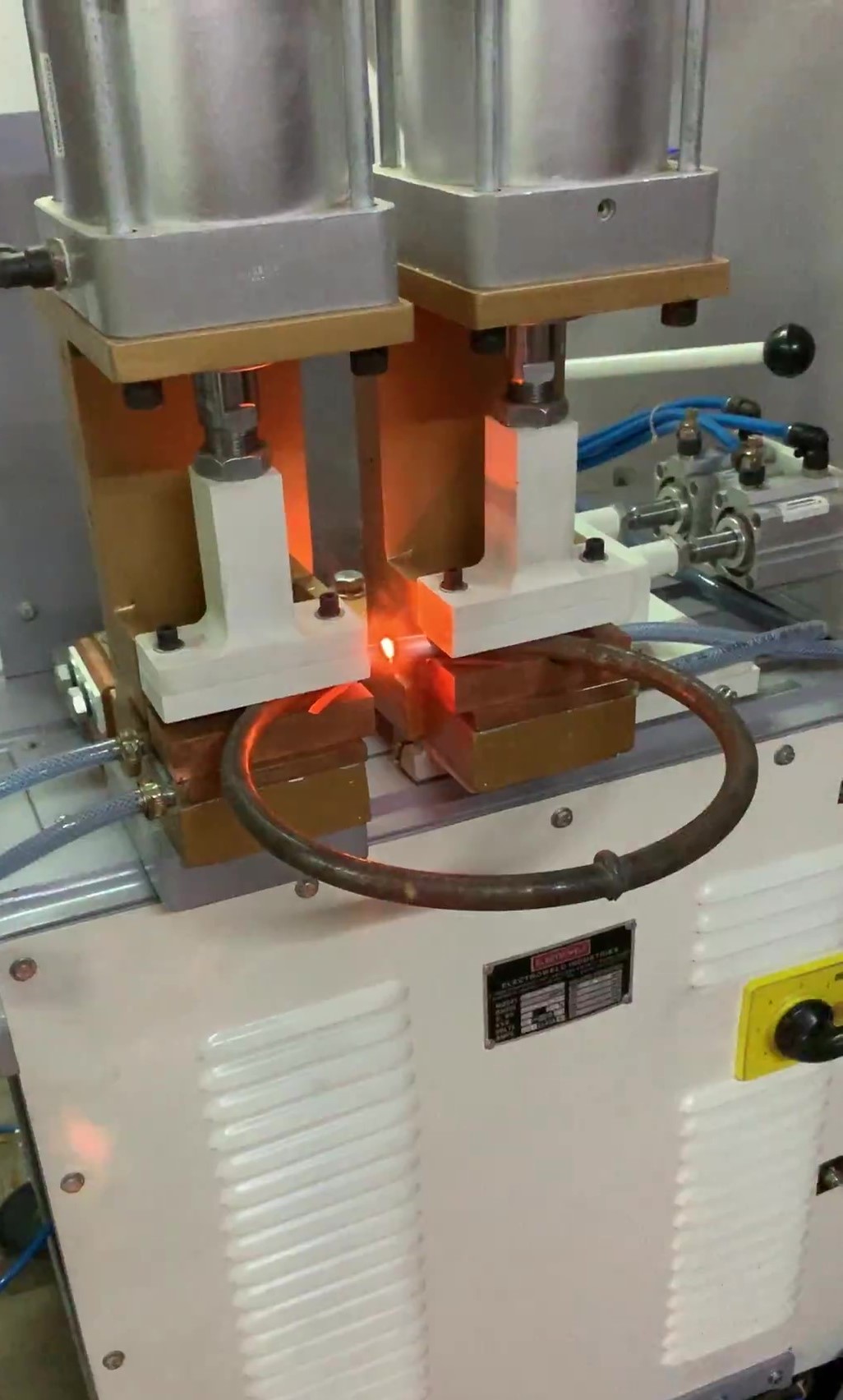

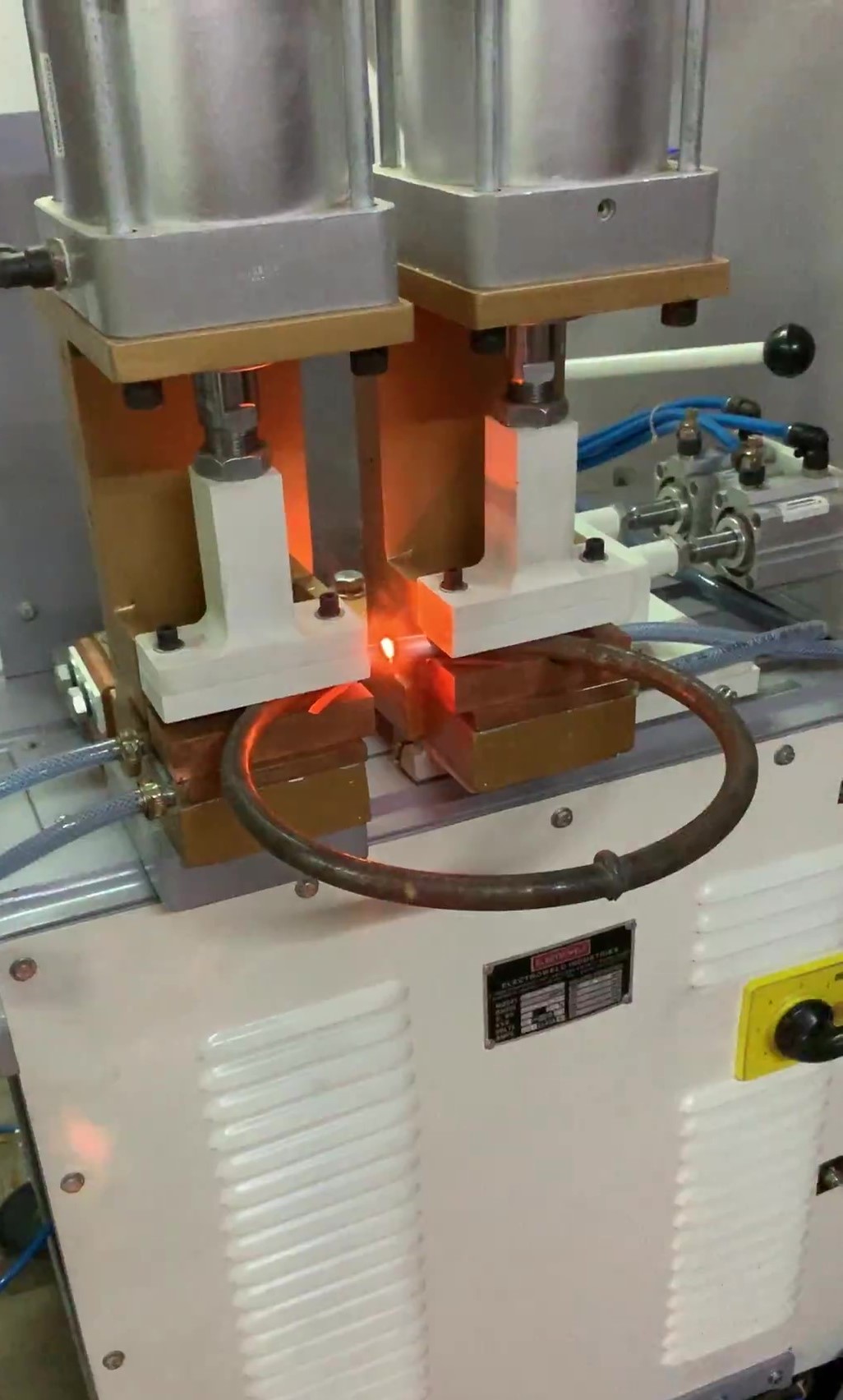

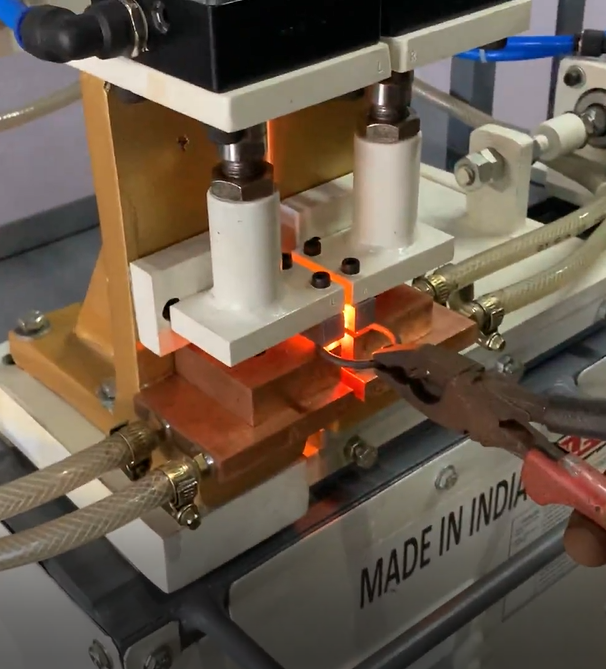

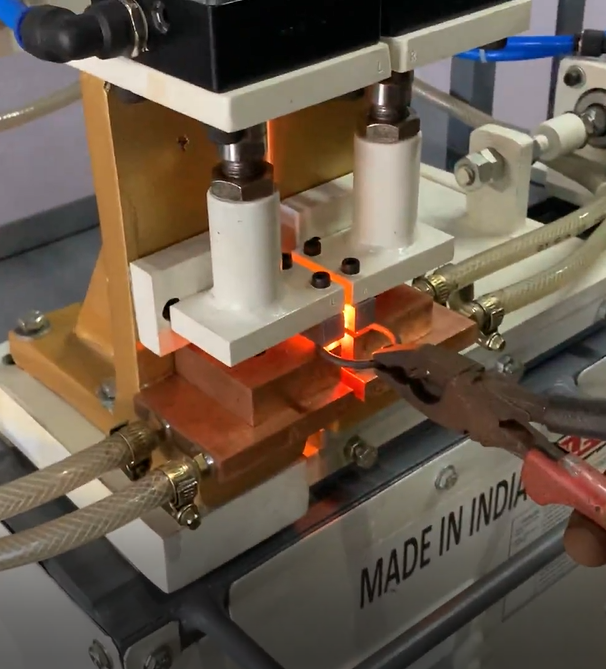

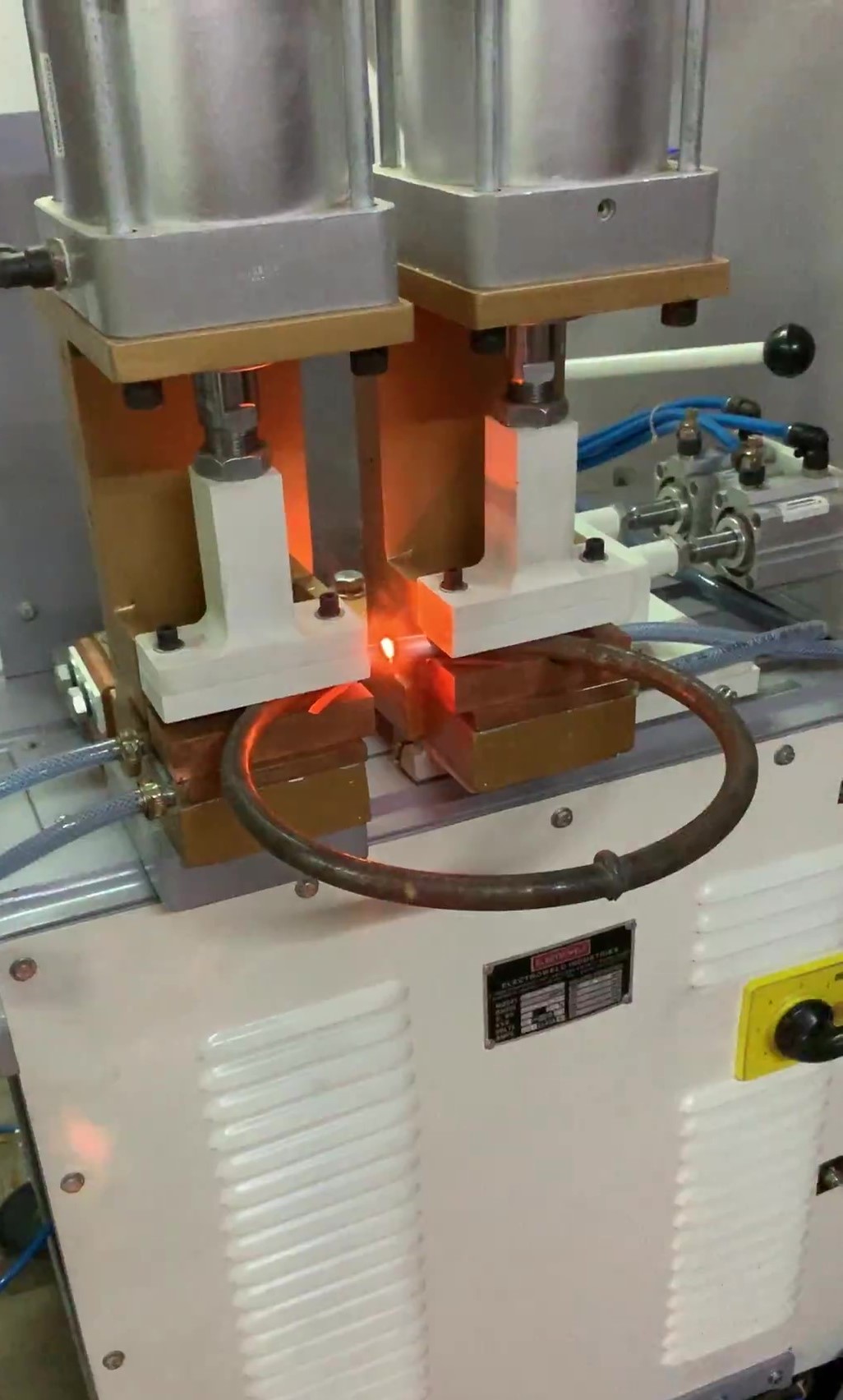

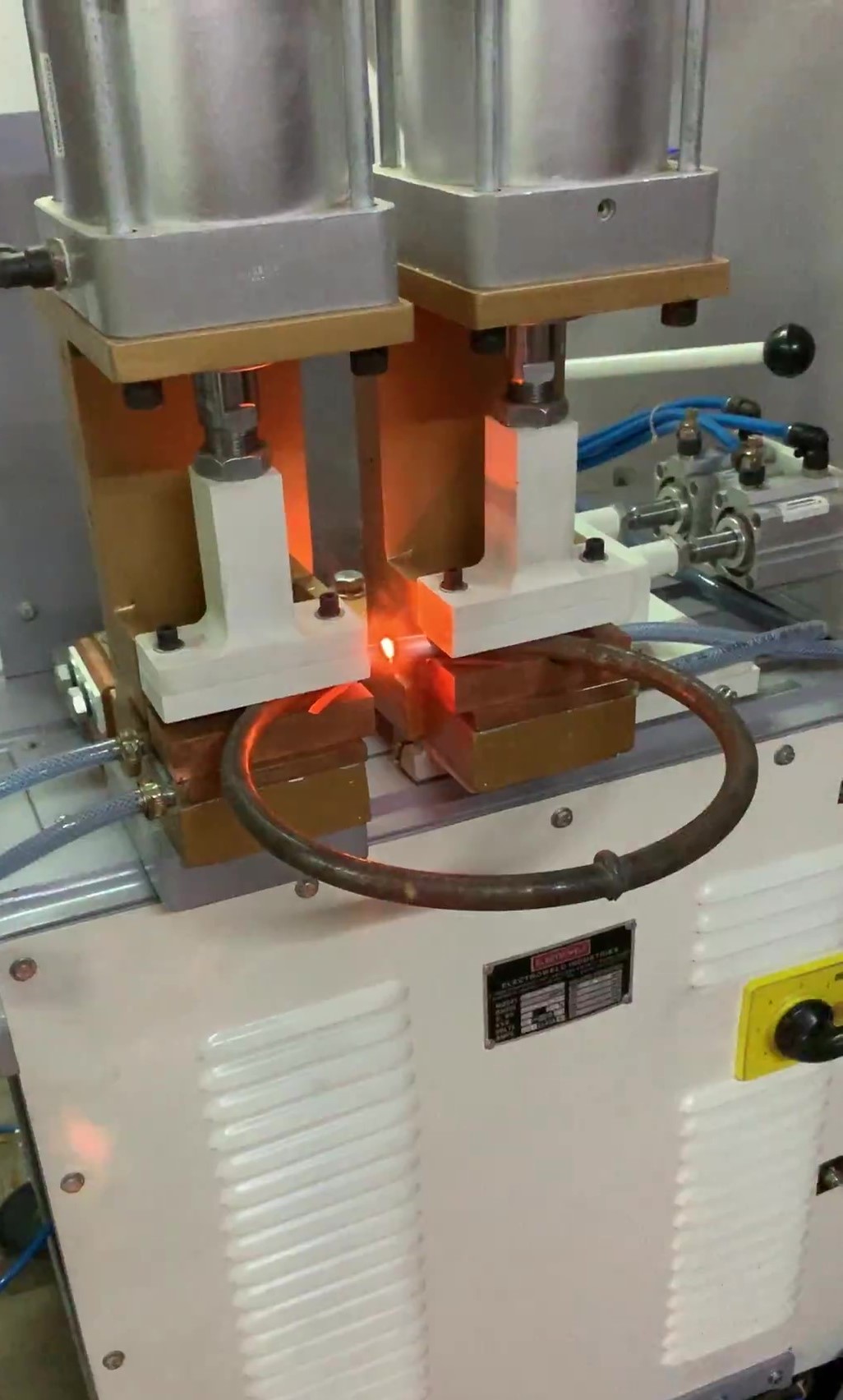

The Machine has 2 welding Jaws with grooves for welding different sized rods. The clamping action of the welding jaws is controlled via the Left and Right Clamping Levers which in turn activate the Pneumatic Clamping cylinders. The machine is also designed with a Horizontal welding cylinder for providing horizontal pressure on the welding jaws during the welding process.

Simple Settings:

1. ELECTRODE SPACING: Adjust lever on indexing plate depending on the diameter of the rod being welded.

2. WELDING CURRENT: Operate knob of the 8 step switch, current making and breaking is automatic via a built-in electromagnetic contactor.

3. UPSETTING PRESSURE: Micrometrically adjustable with pressure control knob for the incoming compressed air line supplying air pressure to the Pneumatic Cylinders.

4. CURRENT ON / OFF: Weld Initiation via Push Button/ Foot Operated Switch and welding duration electronically controlled via timer values.

TIMER AND % HEAT SETTINGS FOR PROGRAMMING THE AUTOMATIC WELDING CYCLE

Following is the sequence of timers which trigger sequentially once the butt welding process is initiated via the pushbutton or foot operated switch:

(A) 'Squeeze 1' Timer (Setting range on 0-100 scale: 0-2 seconds): Timer for initiating clamping of the job via the 2 Vertical Clamping Pneumatic Cylinders. The clamps engage once the timer expires

(B) 'Weld 2' Timer (Setting range on 0-100 scale: 0-120 seconds or 0-360 seconds-depending on machine): Timer for setting the weld cycle time for the duration of the current applied to the weld job. This timer is sequentially triggered once the Vertical Clamping cylinders have clamped the welding job after the 'Squeeze 1' timer expiry. Additionally the initialization of this timer also triggers the activation of the Horizontal Pneumatic Cylinder which provides Upset Pressure for Butt Welding. On expiry of this timer the welding current is stopped.

(C) 'Forge 1' Timer (Setting range on 0-100 scale: 0-2 seconds): Timer for releasing the clamping of the job via the 2 Vertical Clamping Pneumatic Cylinders. This timer is triggered in sequence once the 'Weld 2' timer expires and this timer disengages the 2 Vertical Pneumatic Clamping Cylinders on 'Forge 1' timer expiry.

(D) 'Forge 2' Timer (Setting range on 0-100 scale: 0-2 seconds): Timer for releasing the upset pressure the job via the Horizontal Upset Pressure Pneumatic Cylinder. This timer is triggered in sequence once the 'Forge 1' timer expires and disengages the Horizontal Upset Pressure Pneumatic Cylinder on 'Forge 2' timer expiry.

Following setting controls the % of welding current applied to the job during the welding process when 'Weld 2' timer is engaged:

(E) % Heat Setting (Setting range on 0-100 scale: 0-100%): Weld Power setting adjusted depending on Diameter of Rod being welded.

Welding Process:

The Machine is provided with a toggle switch to alternate between Welding and Annealing functionality. The actual Welding or Annealing is is initiated with a common push button switch.

1. Fix the above simple settings, clamp the job end-to-end in the center of the welding jaws.

2. Press the welding push button and the welding then takes place automatically. Unclamp Job.

3. To anneal, put spacing lever to max. position. Clamp Job centrally in the Pneumatically Clamped Welding Jaws or the provided Annealing Jaws. Press the annealing push button till annealing temperature is reached.

Design Features:

UPSET TRAVEL: Movable platen travel on parallel guides.

UPSET PRESSURE: Provided by the Horizontal Pneumatic Cylinder and adjustable with a knob controlling the incoming air pressure.

CLAMPS: Lever operated adjustable 'floating' steel clamps of precision quick acting design ensure firm preset clamping pressure. Release is quick and easy. Foot operated switch operation also supported for clamping operation if required.

ELECTRODES: Special wear resistant copper alloy electrodes provided with precision 'V' grooves, permit rapid and accurate alignment of wires/rods/cables/blades..

WELDING CURRENT ADJUSTMENT: By means of a 8 step rotary switch from 50% to 100%.

ELECTRODE SPACING: Obtained with ease by a lever set against an indexing plate, adjusting in 10 steps.

WELD CURRENT INITIATION: By pressing welding / annealing push button after clamping the job to weld position simply starts the automatic welding cycle. Foot operated switch operation also supported for weld initiation operation if required.

ELECTRONIC CONTROLS:

(A) Thyristorised synchronous electronic sequence timer consisting of: Squeeze, weld, forge, Weld/No-Weld and heat control unit range 1-99 c/s. This is a standard controller offering.

(B) Solid State - three timers provided for squeeze, weld and forge timings - short range 5 - 50 cycles - long range 1 - 10 seconds (50 to 500 cycles). This is a standard controller offering.

(C) Optional Electroweld AY-01 Digital Timer with capability to store upto 25 different weld schedules. This option will replace the standard controller at an additional cost.

(D) Optional Forwel AK-54V Constant Current Digital Controller with capability to store and recall upto 15 different weld schedules (additional cost). This option will replace the standard controller at an additional cost.

CURRENT CUT OFF: Adjustable over a wide range by means of micrometric thimble the setting of which is read on a graduated scale.

ANNEALING FACILITY: Annealing on same welding jaw setup for Low Carbon Steel Rods. For High Carbon Steel, Copper, Brass and Aluminum annealing can be done using the annealing electrodes with screw type clamps provided for ease and quick annealing of the welded job ensuring a flexible zone at both ends of the weld.

PORTABILITY: The machine is mounted on a four wheeled chassis for easy portability.

Brand New Electroweld Pneumatically Operated Ring Butt Welder 100kva (rngw-100pn) Unlock 80% Savings [XelsjczL]

Weldability - Mild Steel: 19mm-28mm, High Carbon Steel: 12mm-18mm, Copper: 12mm-18mm, Brass: 13mm-19mm, Aluminium: 13mm-21mm.

* Power Requirement is 220V AC 50/60Hz or 415V AC 50/60Hz depending on machine KVA rating

* Prices Include customization for USA 3-Phase 2-Line 220V AC (± 10%) or 440V AC (± 10%) 50/60 Hz

* Prices Include customization for Specific Power Supply requirements for other Regions

* Butt Welders up-to 30KVA can operate on either 2 Line/ 2 Phase 220V (± 10%) or 415V (± 10%) 50/60 Hz

* Butt Welders greater than 30KVA can only operate on 2 Line/2 Phase 415V (± 10%) 50/60 Hz

****Additional set of spares and consumables can be quoted to be added to the shipment as required

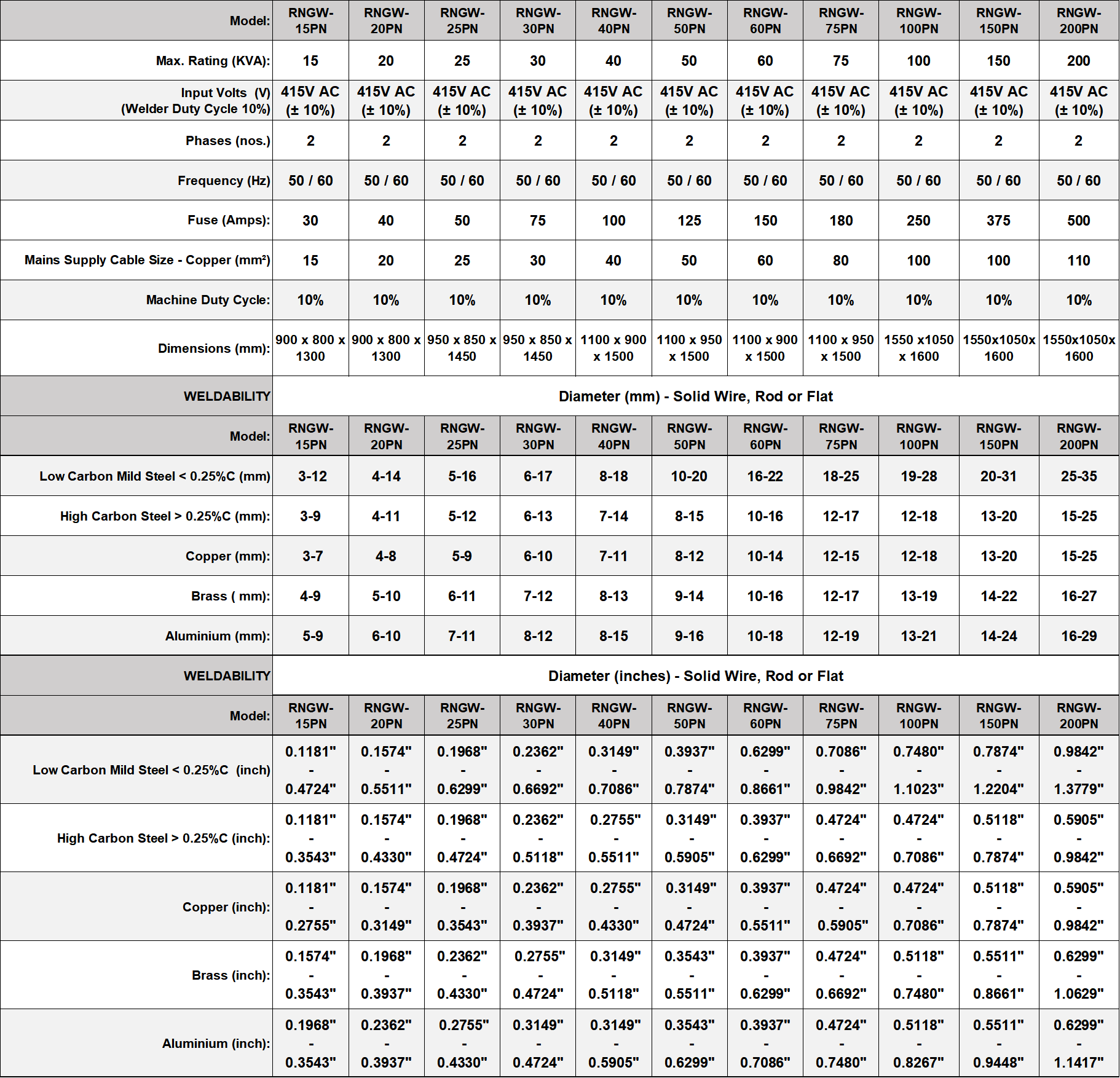

Specifications Table:

Weldability - Diameter of the Solid Wire or Rod - Thickness of Ring (mm):

***Duty Cycle can be higher upto 50% with water cooling active on Welding Jaws and the transformer secondary coils.

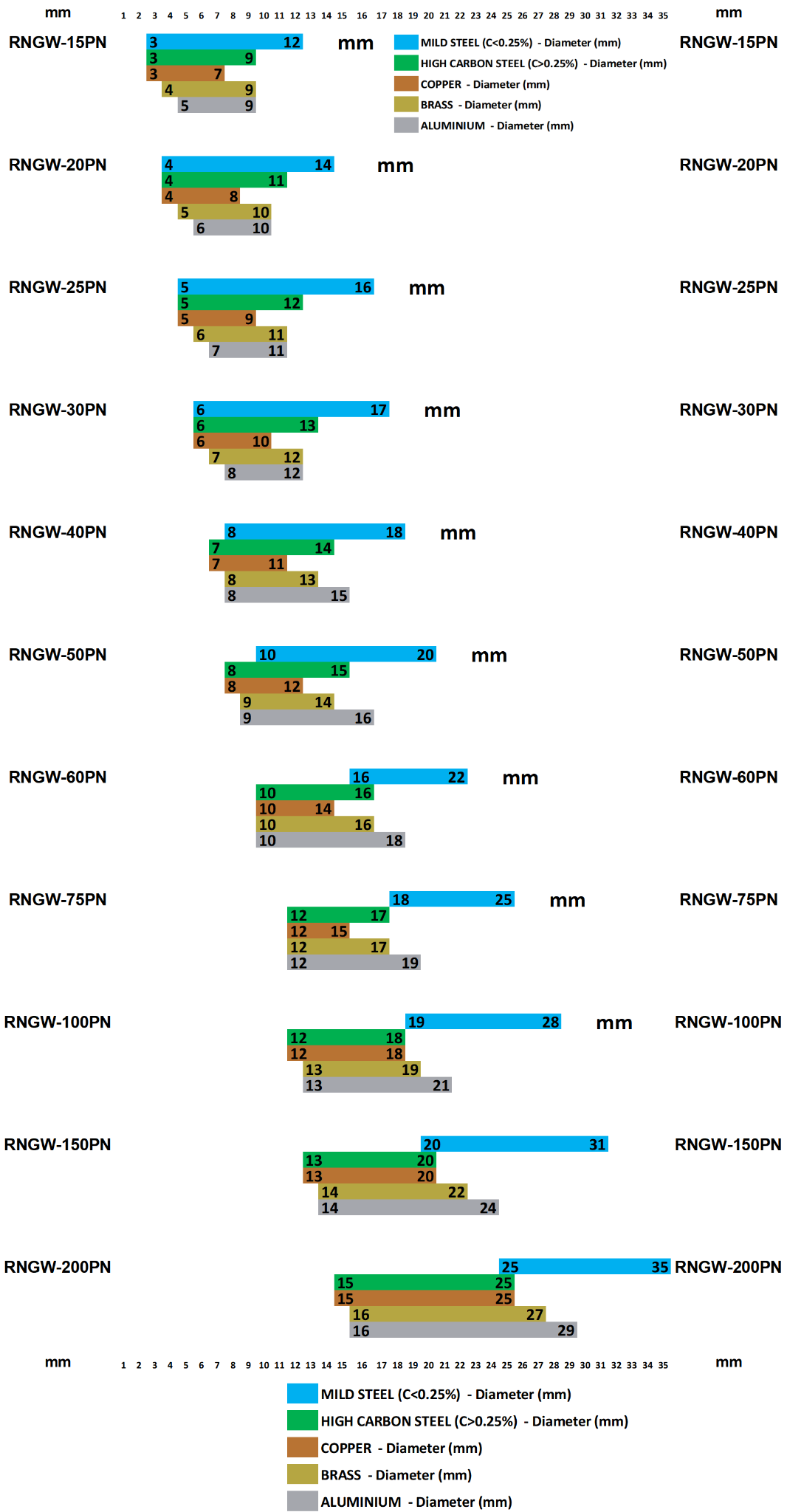

Product Finder - Diameter of the Solid Wire or Rod - Thickness of Ring (mm):

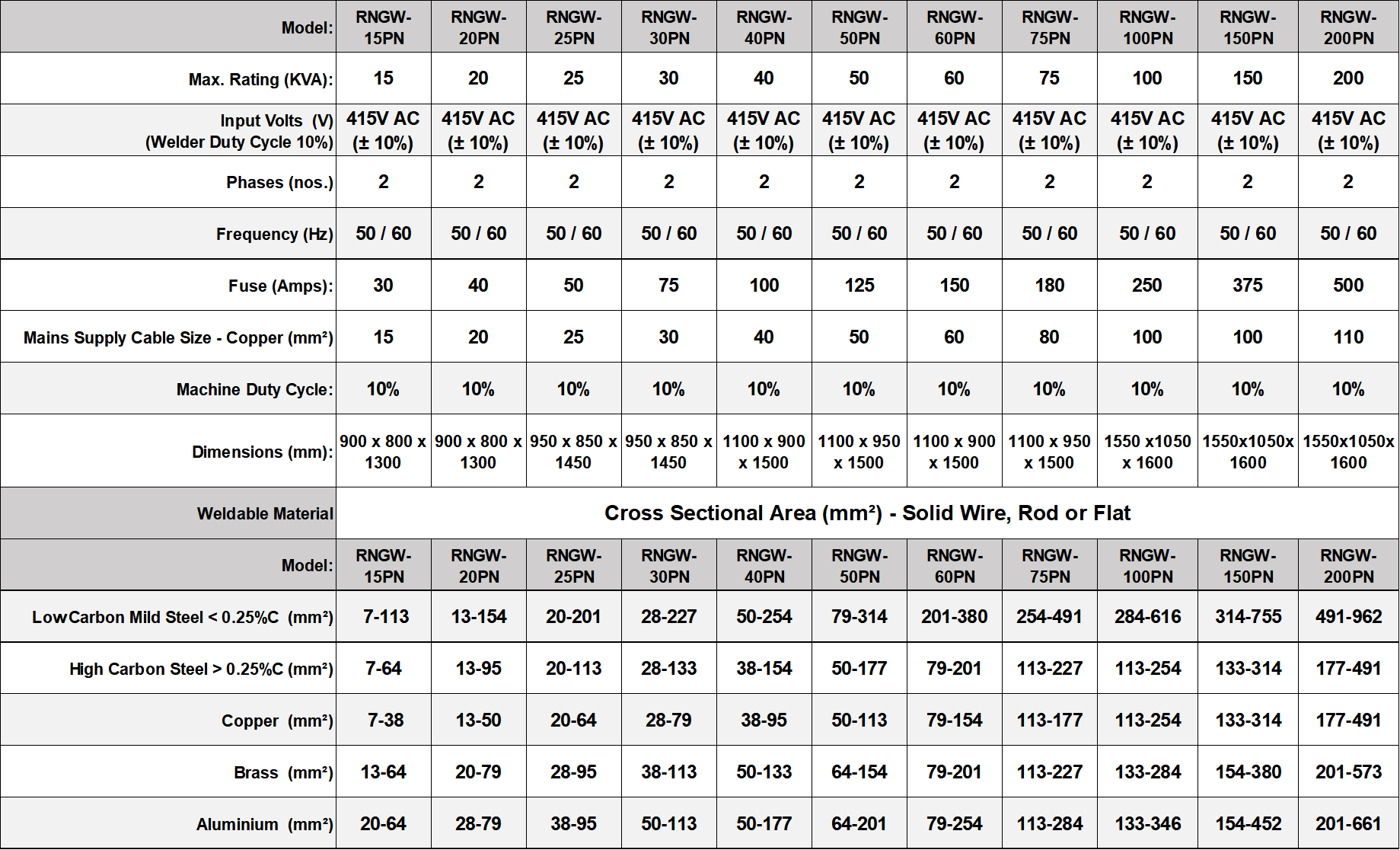

Weldability - Cross-Sectional Area of the Solid Wire, Rod or Flat (mm²):

***Duty Cycle can be higher upto 50% with water cooling active on Welding Jaws and the transformer secondary coils.

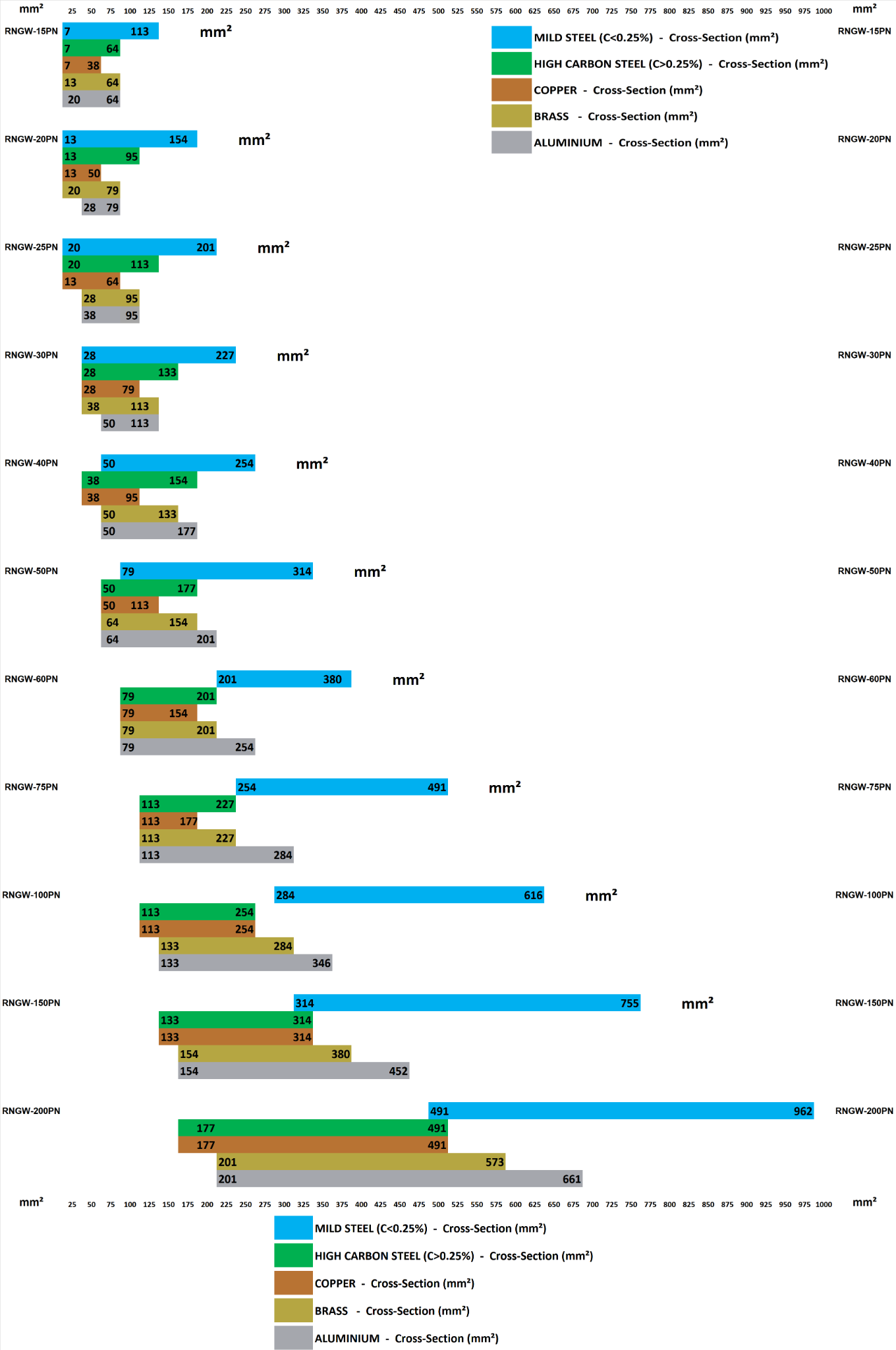

Product Finder - Cross-Sectional Area of the Solid Wire or Rod - Cross-Sectional Area of Ring (mm²):

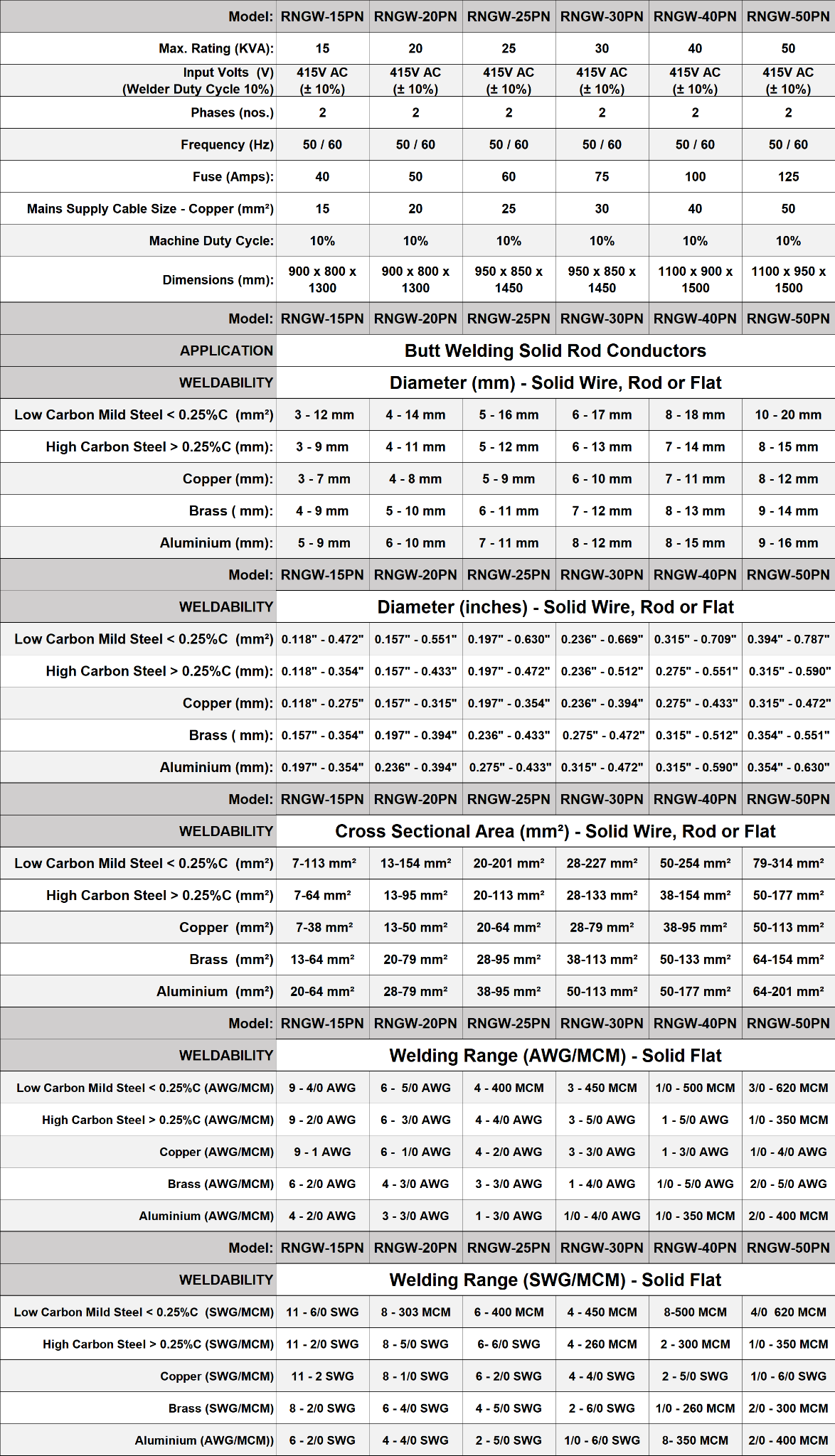

Expanded Specifications Table (Part1):

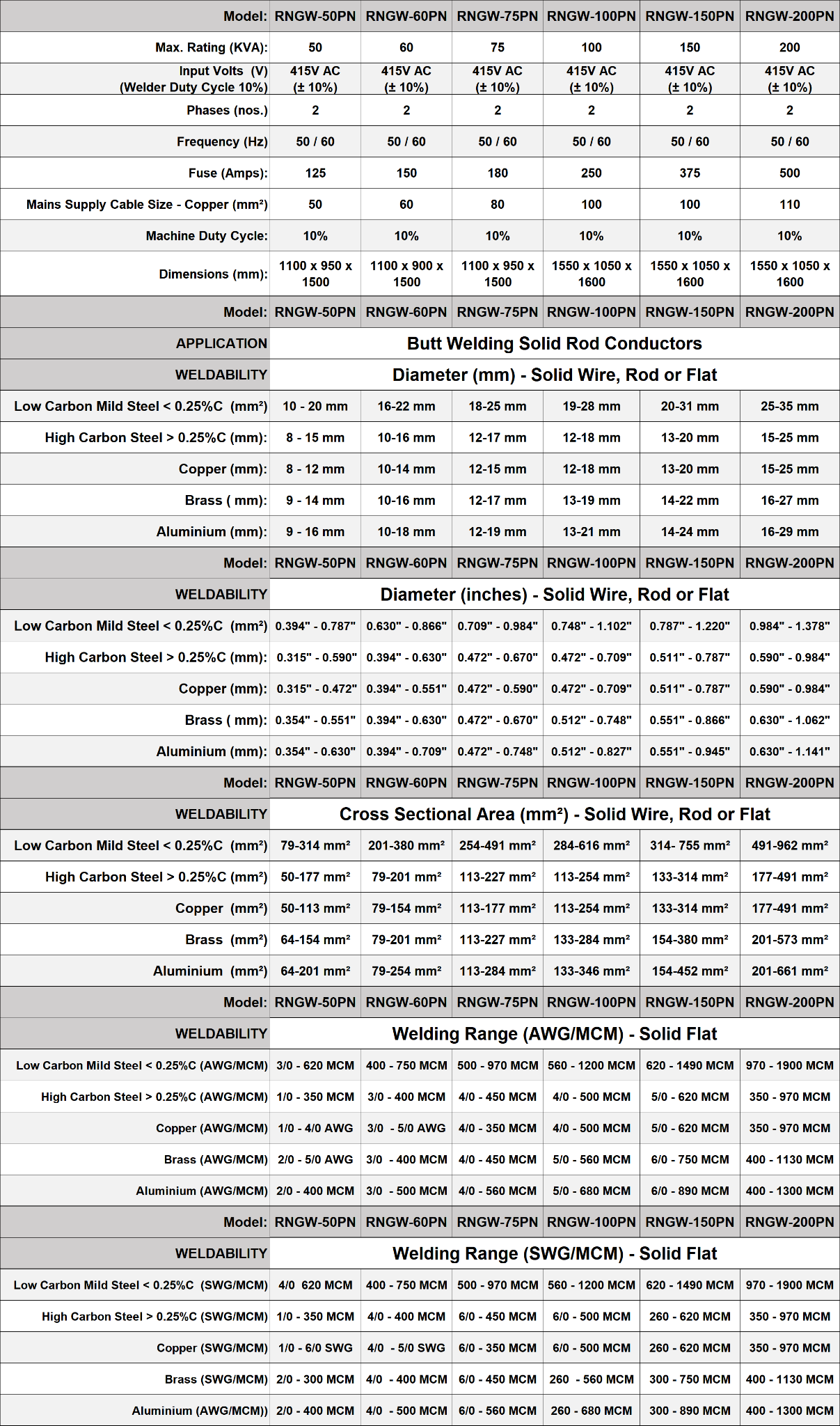

Expanded Specifications Table (Part2):

Optional Functionality

***Weldability - Flat Metal - All Electroweld Wire and Rod Butt Welders can weld Flat Metal jobs when customized with a flat jaw assembly instead of the standard jaws with grooves for wires and rods. For weldability ranges please contact us with the material and cross-section surface area.

****Weldability - Stranded Cables/Ropes/Cords Butt Welding using Glass Sleeves, Ceramic Sleeves or Carbon Sleeves which function as crucibles during the Stranded Cable Butt Welding Application- For weldability ranges please contact us with the material and cross-section surface area.