Electroweld industries is a leading manufacturer of resistance welding equipment, serving the industry for over 45 years. Our welding machines are designed to provide a production solution at an affordable price while ensuring reliability and low cost maintenance.

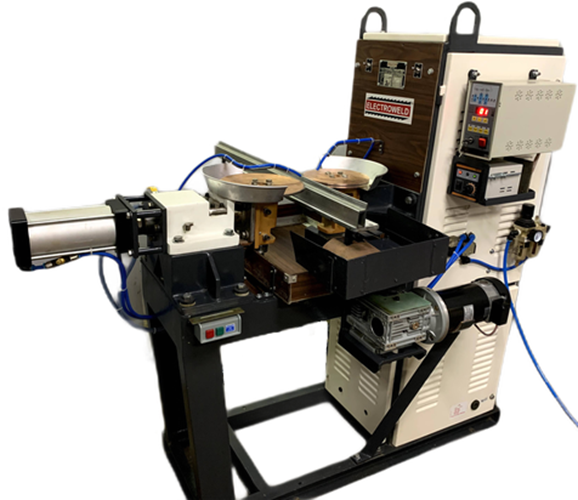

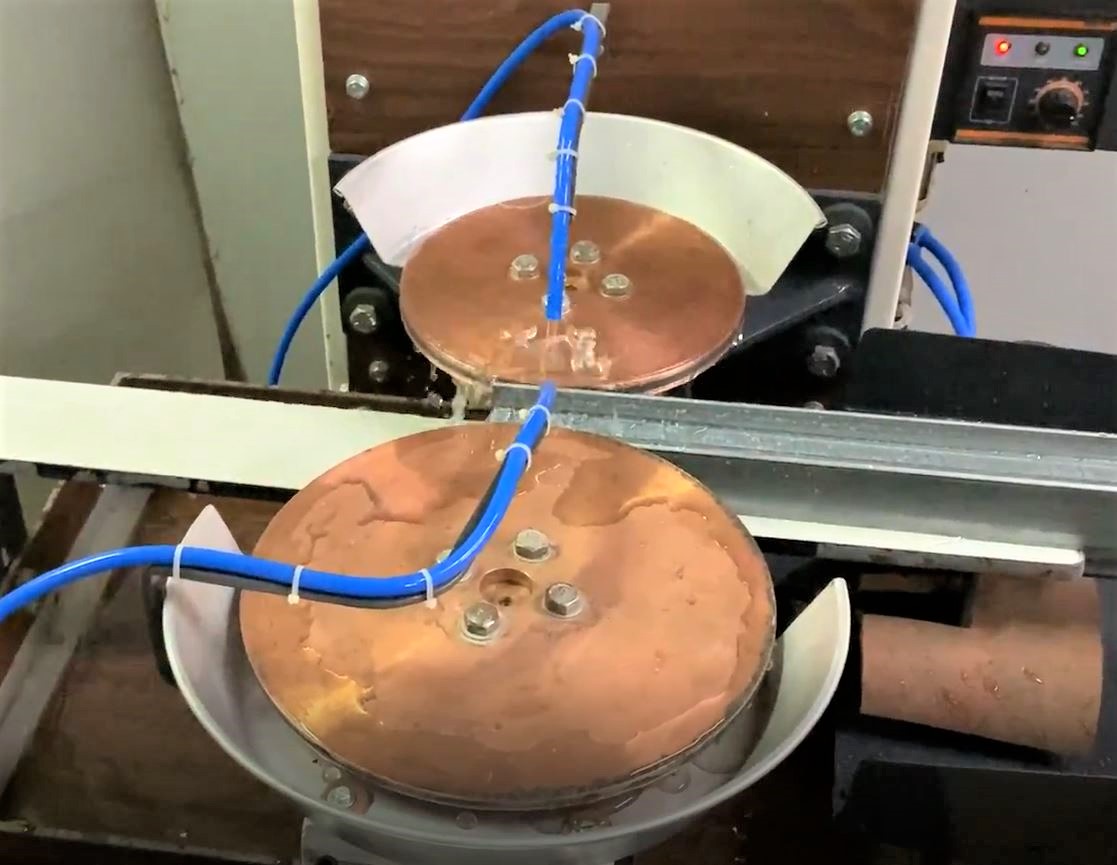

Applications: This 100 KVA Electroweld Roll-Spot Seam Welder is designed for seam welding of different metals with a thickness ranging from 1.25mm + 1.25mm to 1.6mm + 1.6mm. Seam welding uses a wheel-shaped electrode to make either a series of overlapping spot welds to form a continuously welded and leak tight seam - Continuous Seam Welding or a number of spot welds spaced apart – Roll-Spot Seam Welding. With Roll-Spot seam welding, the spot welds are not sealed joints. If a completely leak proof seam is required then the frequency is increased and a continuous seam is created.

Resistance seam welding finds its application in the assembly of fuel tanks as it needs to be liquid-tight. It is also used for welding parts of vessels that need to be water or airtight. The other common application is in welding pipes and tubes. Resistance seam welding is especially used in this field because it doesn’t use any fusion metals in the process. Hence, there are no weld beads that would ruin the aesthetics of the tubes or pipes. Seam welding is also used in manufacturing sheet metal tanks used as containers for kerosene, gasoline, and other fluids. Both the airtight and liquid-tight welds play a role in such an application. Used in Seam welding a variety of materials for all types of Drums. Barrels. Cans, Tins. Transformers-Radiators, Fuel Tanks. Mufflers. Utensils. Small Pipes etc. Users include manufacturing of filter elements, electric motors, automotive exhaust, vacuum components, water tanks, cryogenic vessels, aircraft components, flexible metal hose, etc.

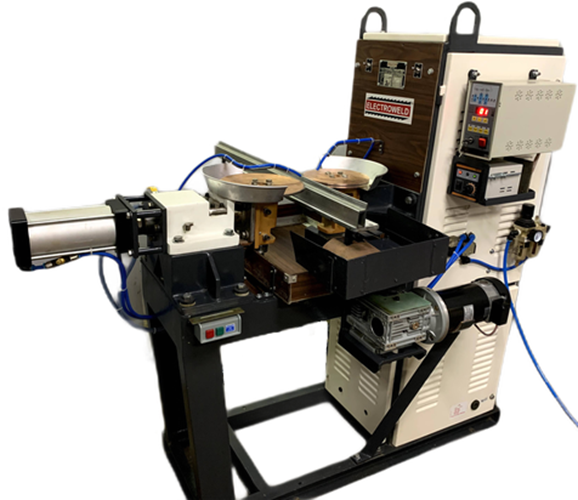

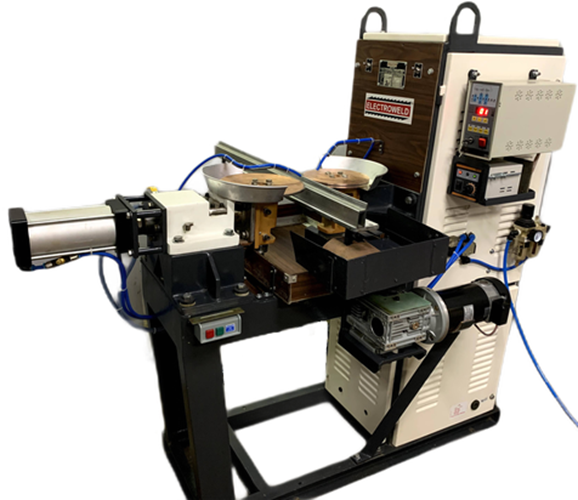

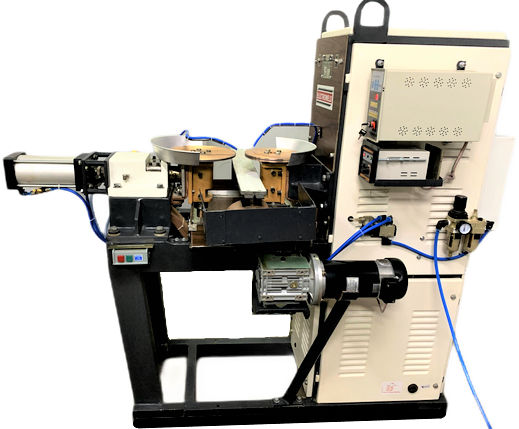

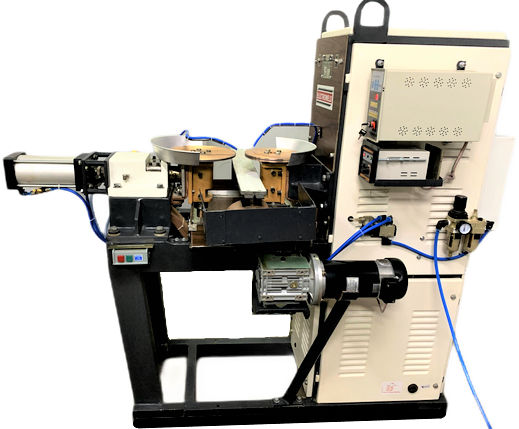

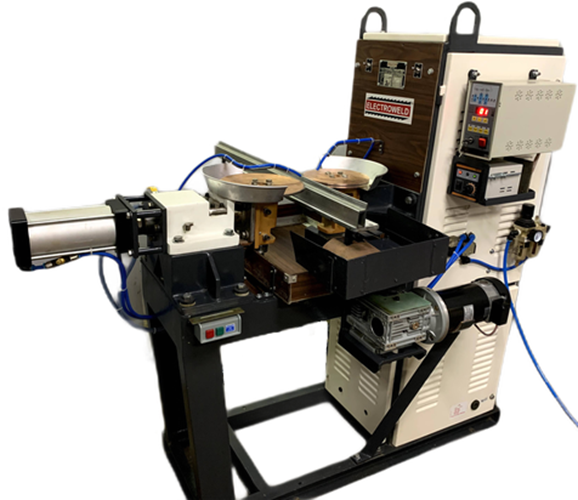

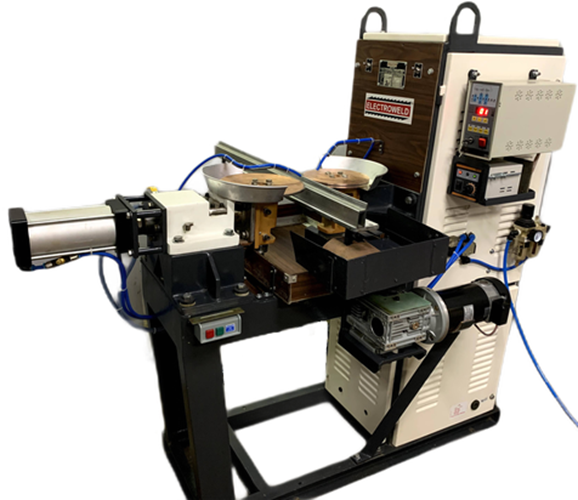

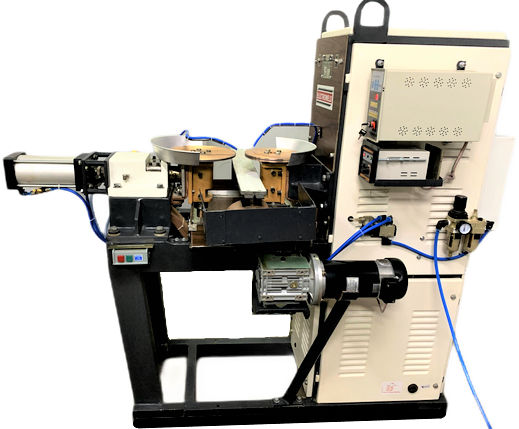

The Perfect Electroweld Horizontal Roll-spot Seam Welder 100kva (smw-100rs) Accessory [YgFjsZPU]

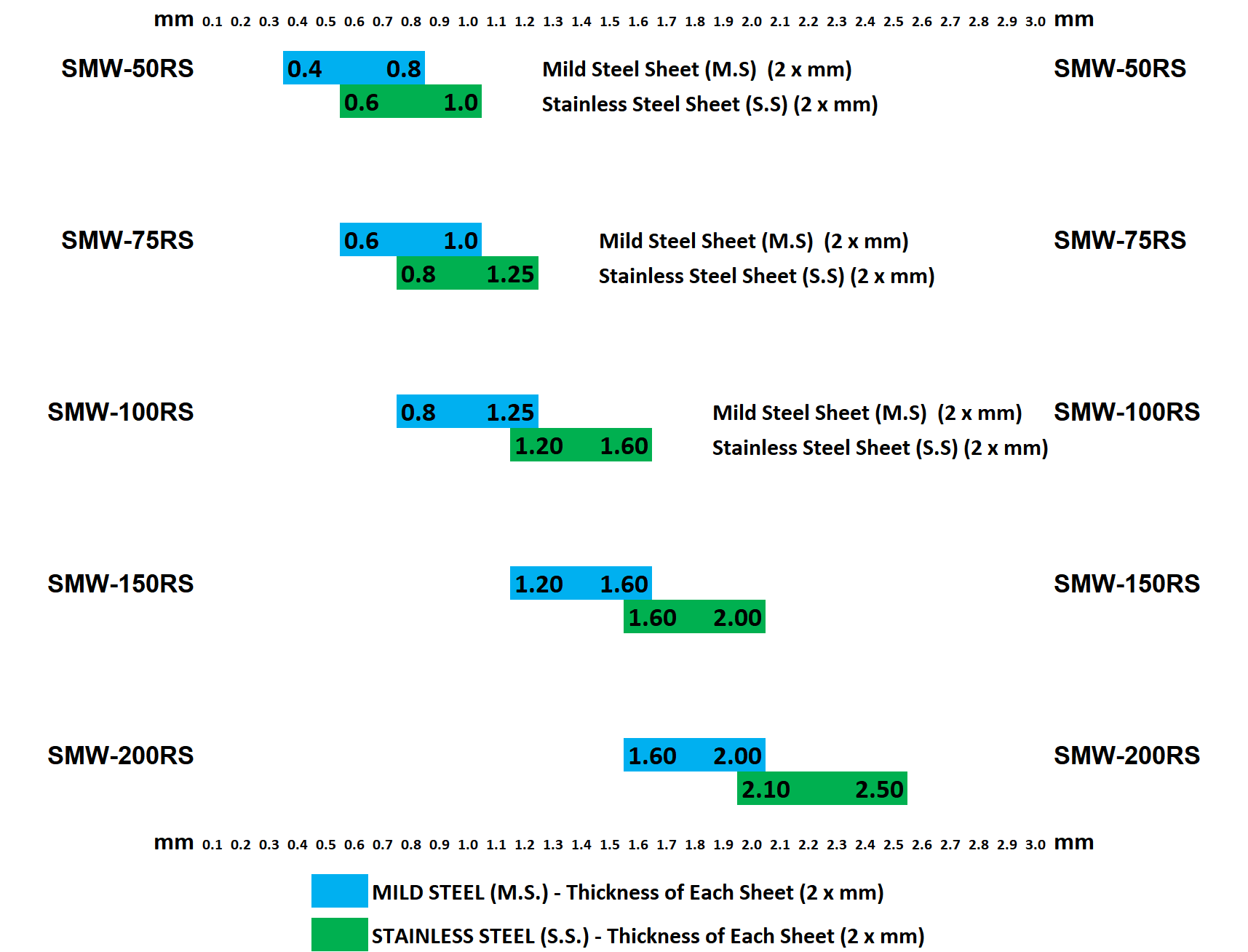

-Weldability Sheet Thickness (mm): M.S Sheet- 1.6mm + 1.6mm, 16 AWG, 16 SWG

-Weldability Sheet Thickness (mm): S.S Sheet- 1.25mm + 1.25mm, 18 AWG, 18 SWG

Weldable Materials: Low Carbon Steel, High Carbon Steel, Galvinised Steel, Tin Plate ,Nickel Alloy, High-Temp Alloy, Aluminum Alloy, Titanium, Brass, Copper.

Advantages of seam welding:

1. Airtight welds: One of the most important characteristics of a continuous weld is that it can create airtight and watertight seals. This is very important in creating metal structures that need air or water leakage protection, like air or liquid-tight vessels.

2. Fast weld process: Weld is possible at high speeds. The process can be fully automated, making it a highly repeatable process and faster than other alternatives like spot welding.

3. No filler/flux required: The weld is possible without using any filler or flux material.

4. It is possible to produce single seam welds and parallel seams simultaneously.The joints created using this welding technique are usually strong and robust.

Types of Seam Welding:

The 2 main types of Seam Welding - Intermittent and Continuous Seam Welding are very similar. In fact they can be run on the same machine. The only difference is the spacing of the weld. A change in the machine settings could produce either weld.

1. Continuous Seam welding:

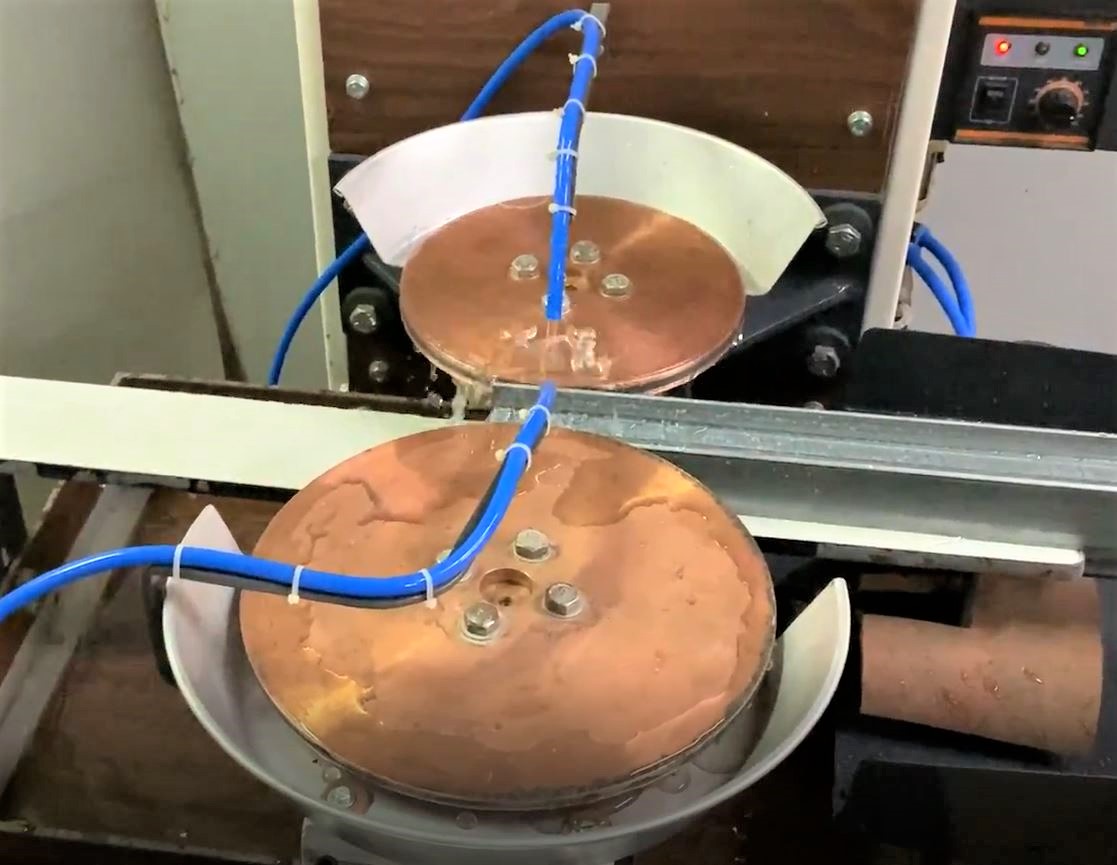

In this welding technique, the electrodes rotate at a consistent and predetermined speed. This is done to create an overlapping weld. To achieve this type of weld timed current impulses are needed to create an overlapping weld. Standard seam welding produces continuous and leak-proof welds. Usually, these final uninterrupted welds can be achieved by carefully rotating the wheel electrodes on the workpiece and using continuous current pulses. Seam welding especially in a continuous mode can be a major power consumer. It can really be surprising the first time you see a drum or dishwasher water tight weld being welded. It may look and sound like the machine is welding continuously but it is not. The equipment is designed for a maximum 50% duty cycle and should not exceed that rating during continous operatuon.

2. Intermittent Seam welding:

Roll Spot Weld is a type of Intermittent Welding. In intermittent seam welding, the current pulses are passed intermittently. The current pulses combined with the pressure created by the wheels create separate spot welds.The pulse frequency of the current determines the spot weld spacing.This type of welding allows the workpiece to move from one weld position to another.This type of seam welding is suited to welding thicker materials and in particular those that are resistant to continuous seam welding. For tack welding the spots are set further apart. With intermittent seam welding, the spot welds are not sealed joints. If a completely leak proof seam is required then the frequency is increased and a continuous seam is created.

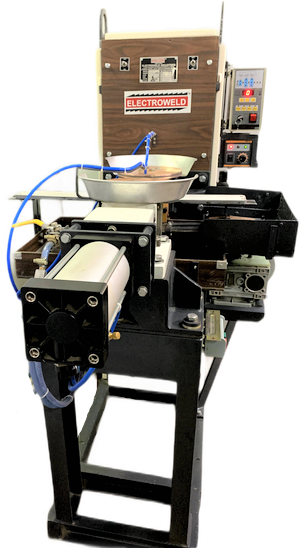

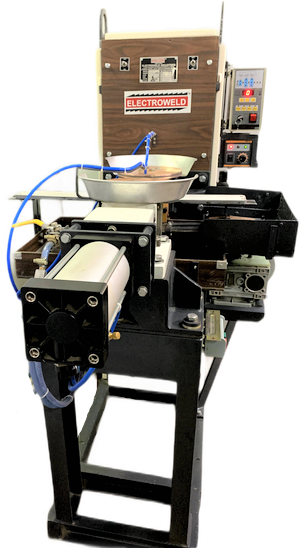

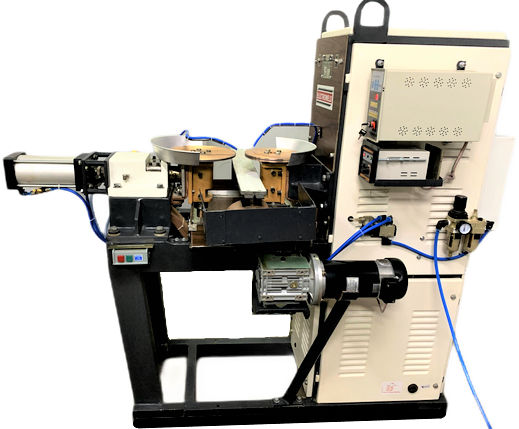

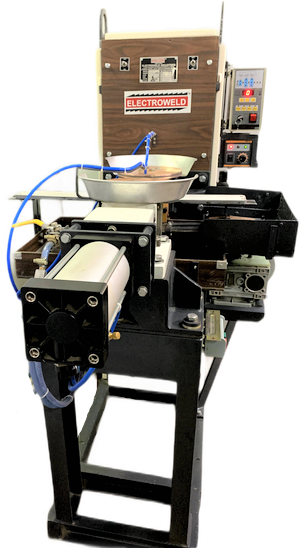

Construction: The machines are constructed with sturdy, all welded steel plate fabrication, suitably braced and stiffened at points of stress. Water Cooled welding transformer having core of high grade electrical steel, primary and secondary coils of solid electrolytic copper of ample section, heavy duty class 'F' insulated and vacuum impregnated, suitable to withstand continuous temperatures of 155 degree Celsius. The transformer is fitted inside the body and upper electrode arm mounted directly on to the body.

WELDING CURRENT ADJUSTMENT: Transformer Primary coil provided with taps brought out to tap change links for adjustment of welding current in 8 steps from 55-100% Tap change link control is enclosed behind machine door.

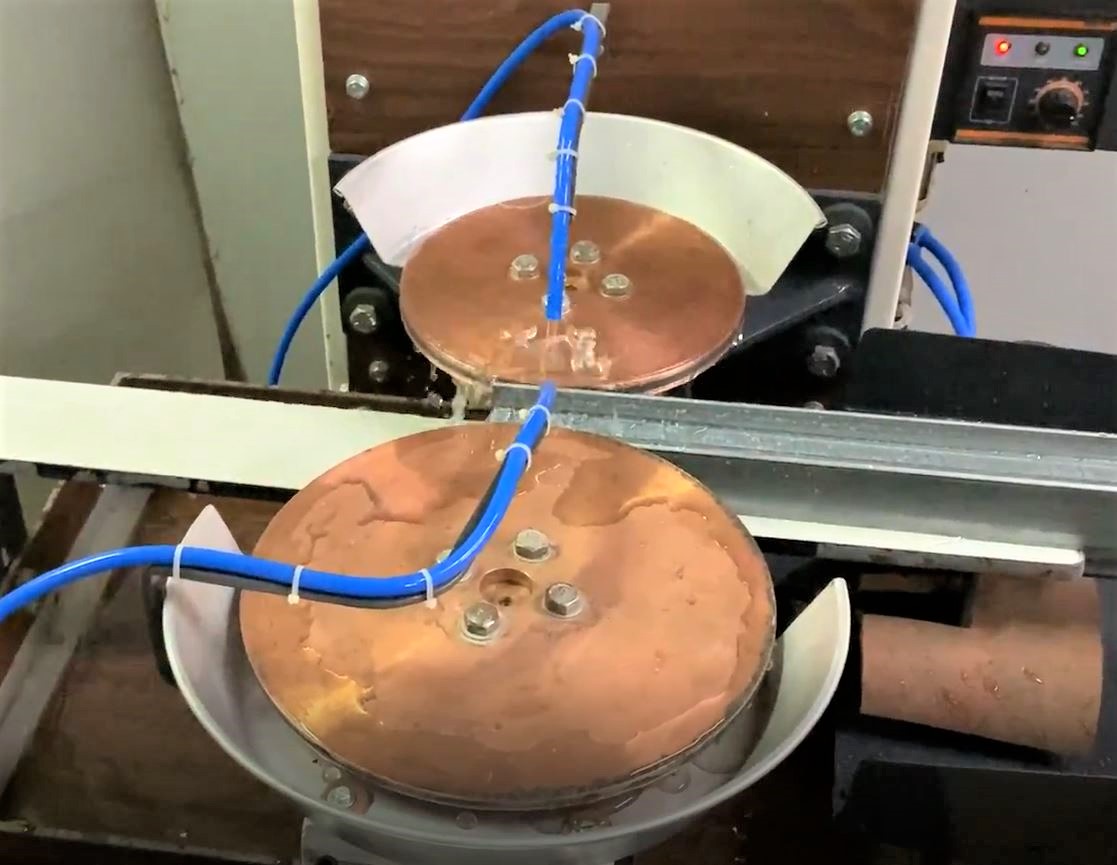

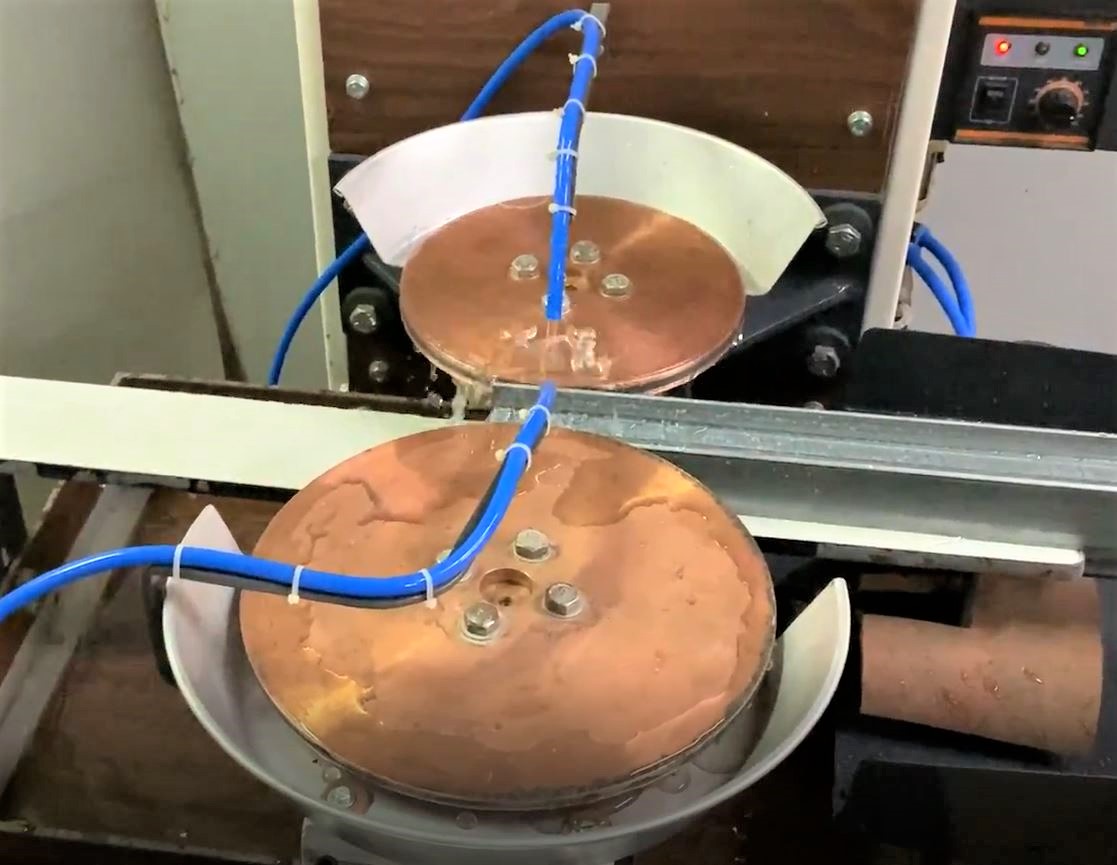

ELECTRODES: Circular Disc type horizontally mounted left and right welding Wheels, of diameter as specified, having easily detachable type bearings to facilitate replacement. One pair of Welding Wheels supplied with the machine.

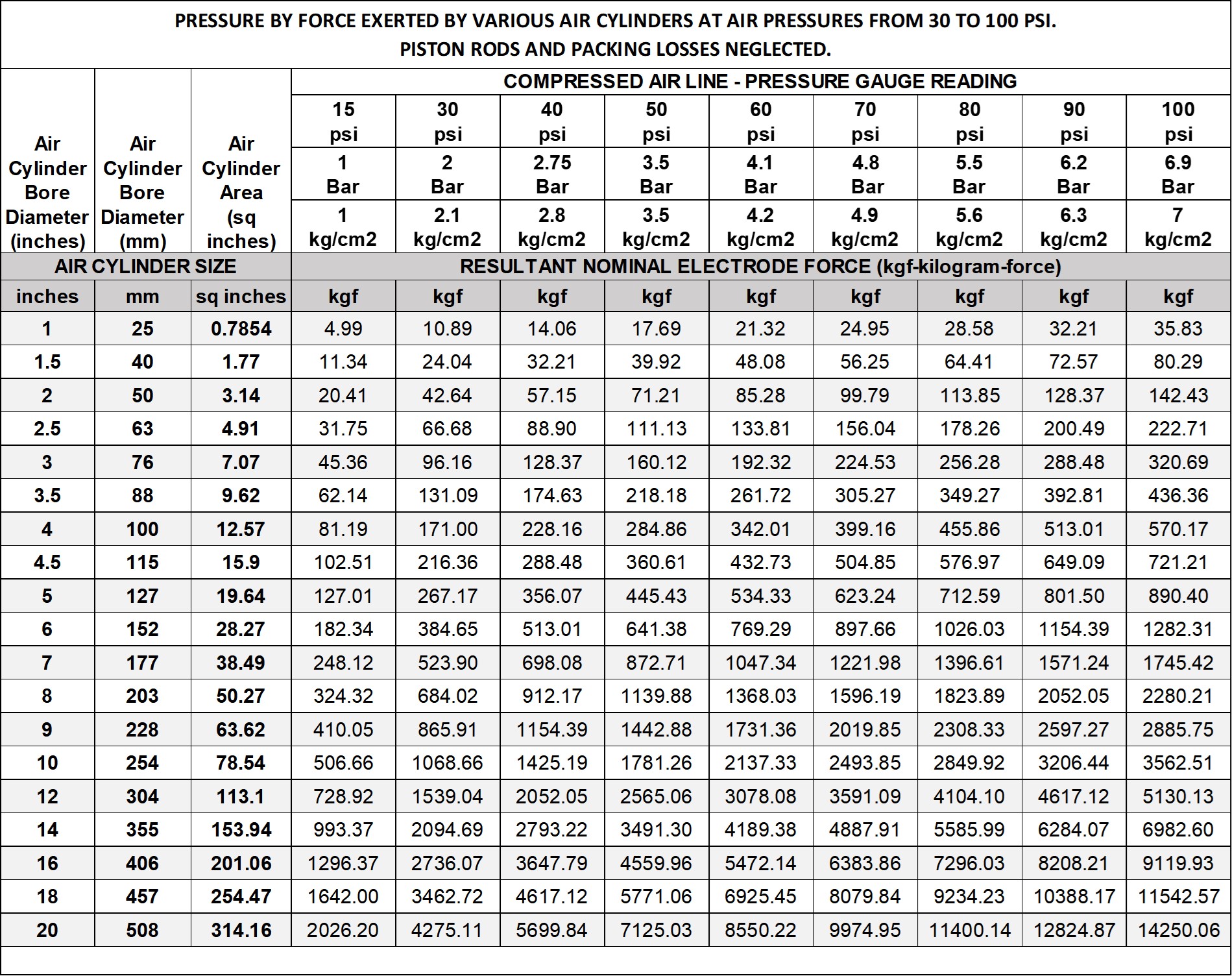

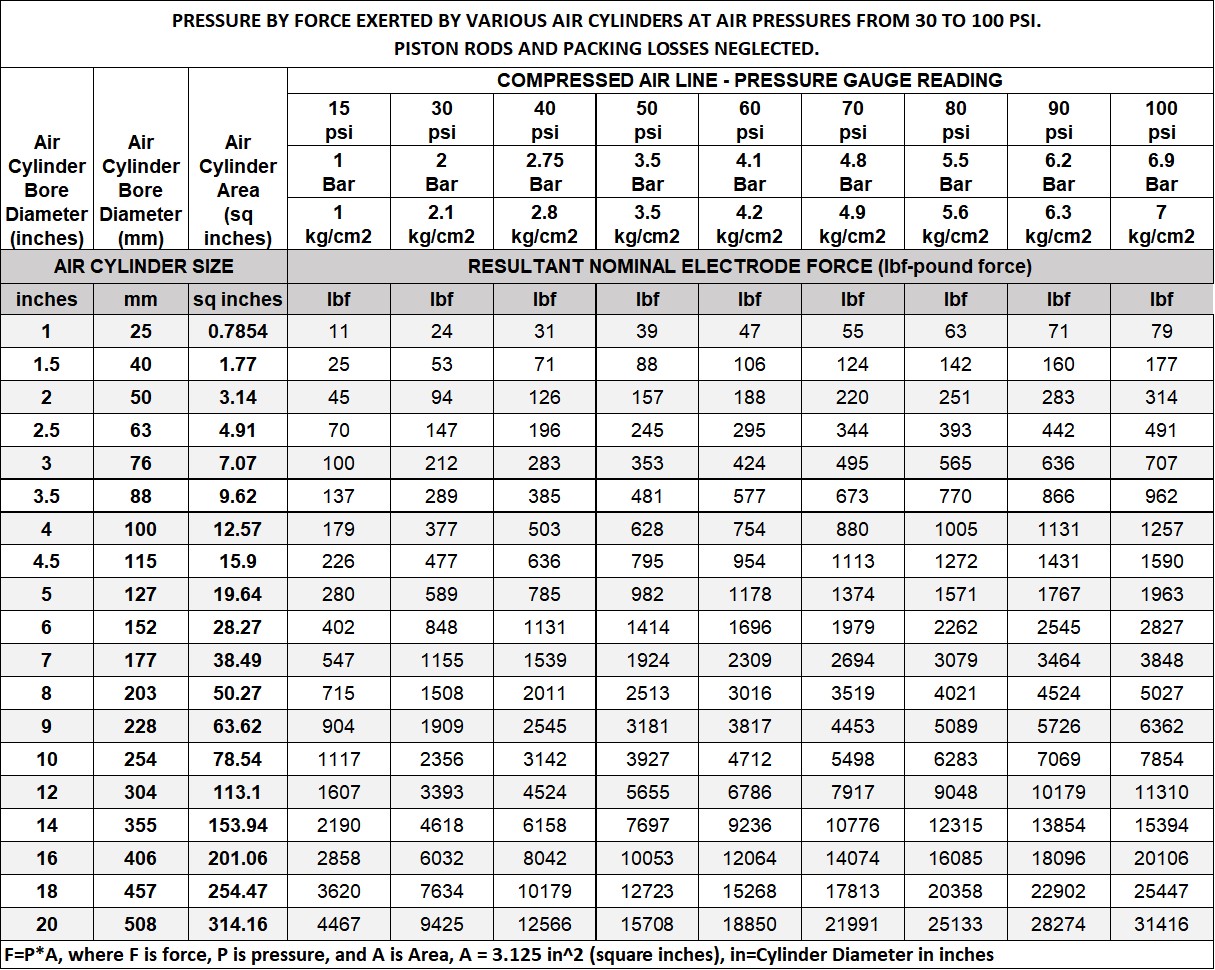

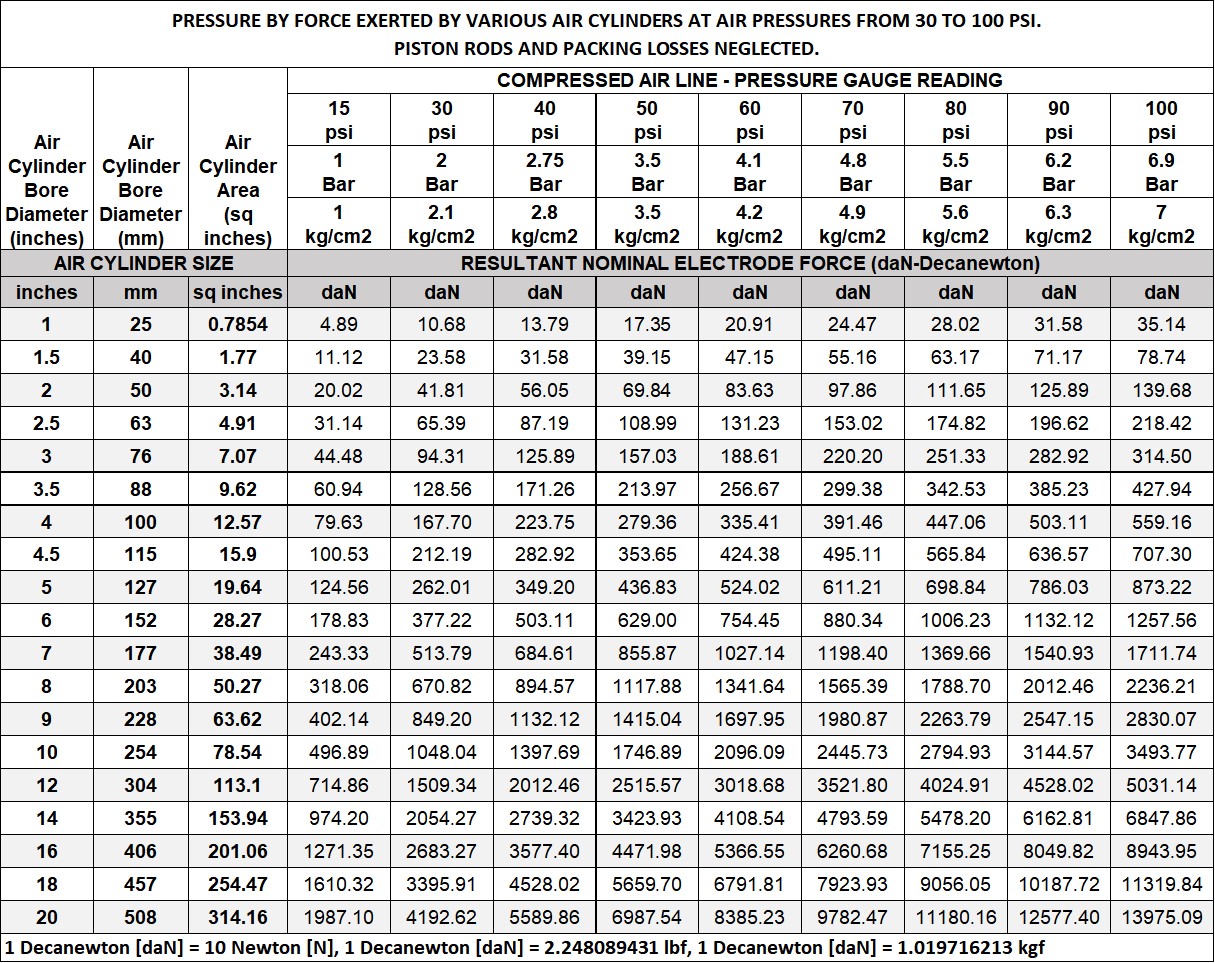

ELECTRODE CONTROL: Horizontal ram of precision low inertia anti-friction type provided with wear compensating features and actuated via a quick follow device by a heavy duty 2-way pneumatic cylinder controlled by an electrically operated solenoid valve. Compressed air at 15 to 110 p.s.i. acting on the pneumatic cylinder provides the necessary electrode force.

ELECTRODE FORCE: By Air Pressure Regulating Valve provided on the Machine.

ELECTRODE DRIVE: Variable speed, reversible gear drive provided on Top or Bottom as required. Drive power from a built in 230 Volt. 1 Phase. PMDC Motor, through variable speed reduction gearing to provide smooth and step-less variation of the welding speed as specified.

ELECTRONIC SEAM WELDING CONTROL:

(A) Thyristorised synchronous electronic sequence timer consisting of: Squeeze, weld, forge, off and heat control unit range 1-99 c/s. This is a standard controller offering.

(B) Solid State - three timers provided for squeeze, weld and forge timings - short range 5 - 50 cycles - long range 1 - 10 seconds (50 to 500 cycles). This is a standard controller offering.

(C) Optional Electroweld AY-01 Digital Timer with capability to store upto 25 different weld schedules. This option will replace the standard controller at an additional cost.

(D) Optional Forwel AK-54V Constant Current Digital Controller with capability to store and recall upto 15 different weld schedules (additional cost). This option will replace the standard controller at an additional cost.

ELECTRONIC DC DRIVE CONTROL:

(A) TDR-96: Seam Welder Wheel DC Drive Controller. This is a standard controller offering.

The Perfect Electroweld Horizontal Roll-spot Seam Welder 100kva (smw-100rs) Accessory [YgFjsZPU]

-Weldability Sheet Thickness (mm): M.S Sheet- 1.6mm + 1.6mm, 16 AWG, 16 SWG

-Weldability Sheet Thickness (mm): S.S Sheet- 1.25mm + 1.25mm, 18 AWG, 18 SWG

Weldable Materials - Low Carbon Steel, High Carbon Steel, Galvinised Steel, Tin Plate ,Nickel Alloy, High-Temp Alloy, Aluminum Alloy, Titanium, Brass, Copper.

* Galvanized Steel Sheet Seam Welding- Galvanizing is a coating of zinc metal that is applied to the steel when it is manufactured, either in a hot dipped fashion or by electroplating. Zinc, when used as a galvanizing coating, protects steel from rust. Galvanized steel requires about 25% more horse power than non-galvanized steel. Weld time and/or weld power need to be increased to spot weld Galvanized steel. Select a higher KVA machine to account for the increased power requirement for seam welding Galvanized steel.

* Power Requirement is 415V AC 50/60Hz(Price includes customization as per requirement before shipping)

**Seam Welders upto 30KVA can operate on either 2 Lines/Phases 220V (+10%/-10%) or 400V (+10%/-10%) 50/60Hz

***Seam Welders greater than 30KVA can only operate on 2 Lines/Phases 400V (+10%/-10%) 50/60Hz

**Standard Throat Depth is 18" (Customizable to 18” / 24” / 30” / 42" at an additional charge before shipment.

***Maximum length of straight line welding job on this welder is 12" - Customizable by ordering the machine with the corresponding throat depth.

****Additional set of spares and consumables can be quoted to be added to the shipment as required

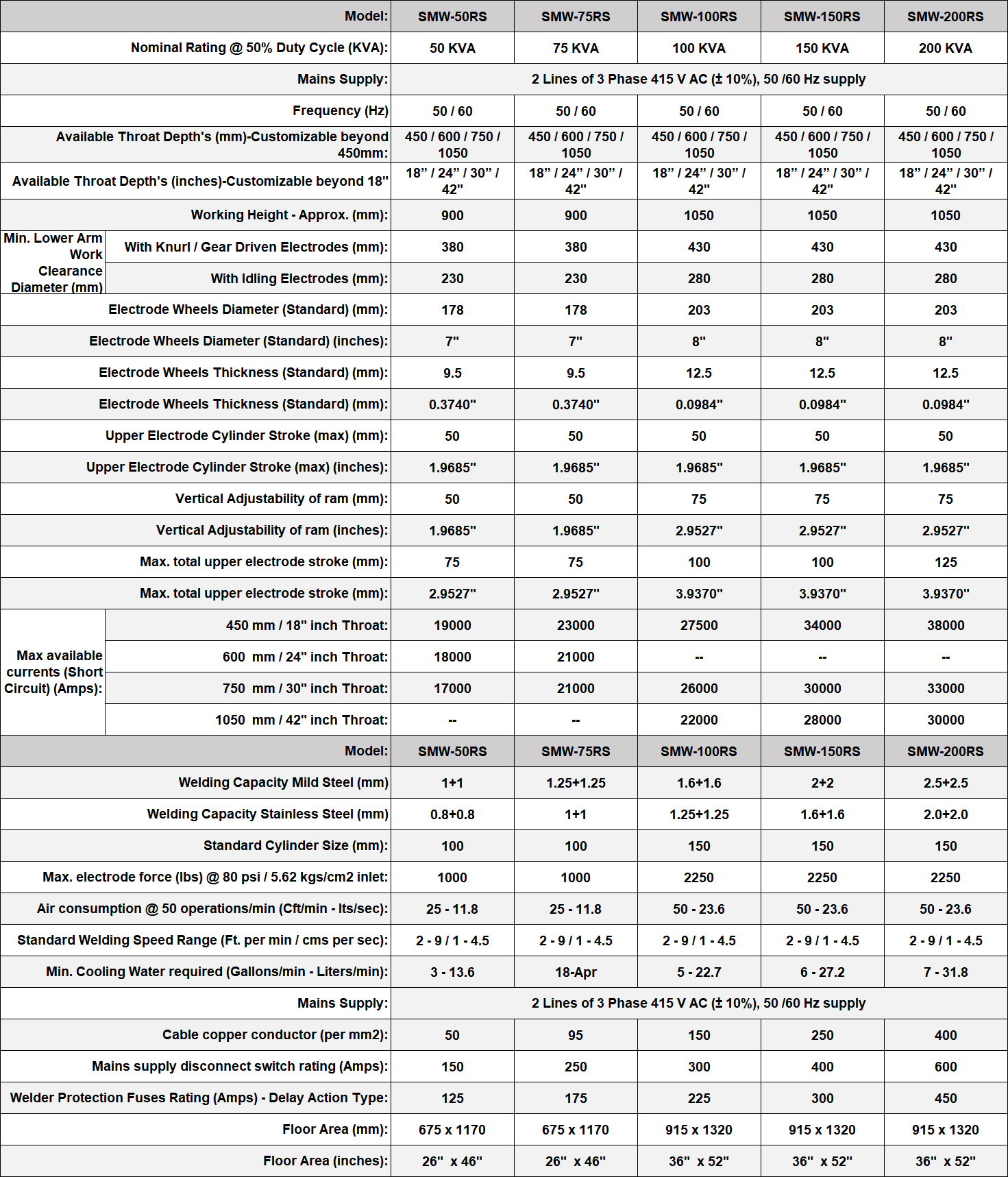

Specifications Table:

What is Seam Welding?

Resistance Seam Welding is a procedure that entails the joining of two similar metals. Seam welding uses a wheel-shaped electrode to make either a series of overlapping spot welds to form a continuously welded and leak tight seam - Continuous Seam Welding OR a number of spot welds spaced apart – Roll-Spot Seam Welding. The requirements on electrodes and surface finish are the same as for spot welding. The shunt effect of the closely spaced nuggets and the short weld times mean that higher currents are necessary than for spot welds. The welding force should be proportional to the hardness of the materials. Hence, harder metals need more welding force compared to softer metals. Thickness limitations: There are limitations when it comes to the thickness of the sheets because seam welding can become quite cumbersome when the thickness of a single sheet is more than 3mm. Note:When welding two different material thicknesses to one another (0.060” to 0.125”, for example), go by the thinner of the two

materials. We are essentially welding the thin to the thick material. This works to our advantage as one can use a smaller KVA rated machine.

How to choose seam weld electrode wheel material?

The type of electrodes used in resistance seam welding is dependent on the material that is to be welded :

1. RWMA Class 2 CuCrZr seam welding wheels are usually used to weld steel alloys,galvanized steel.

2. RWMA Class 3(C18000 CuNiSiCr),C17510 CuNiBe seam weld wheel should be used to weld stainless steel.

3. CuCr (RWMA class 2,C18200) seam weld wheels are ideal material to weld hot-rolled steel.

4. RWMA Class 1 CuZr Copper Zirconium – C15000 seam welding wheels are used to weld highly conductive softer materials (Aluminum).