Electroweld industries is a leading manufacturer of resistance welding equipment, serving the industry for over 45 years. Our welding machines are designed to provide a production solution at an affordable price while ensuring reliability and low cost maintenance.

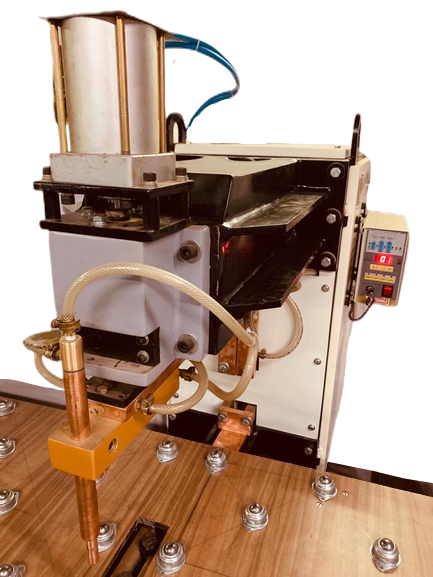

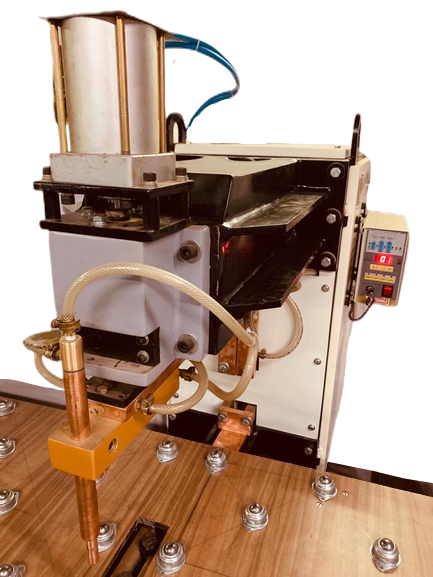

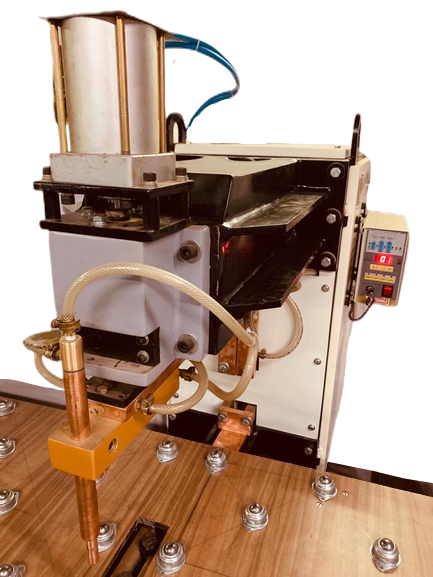

Electroweld Press Type Projection/Spot Welder 50KVA @ 50% Duty Cycle (SPM-50PRE)

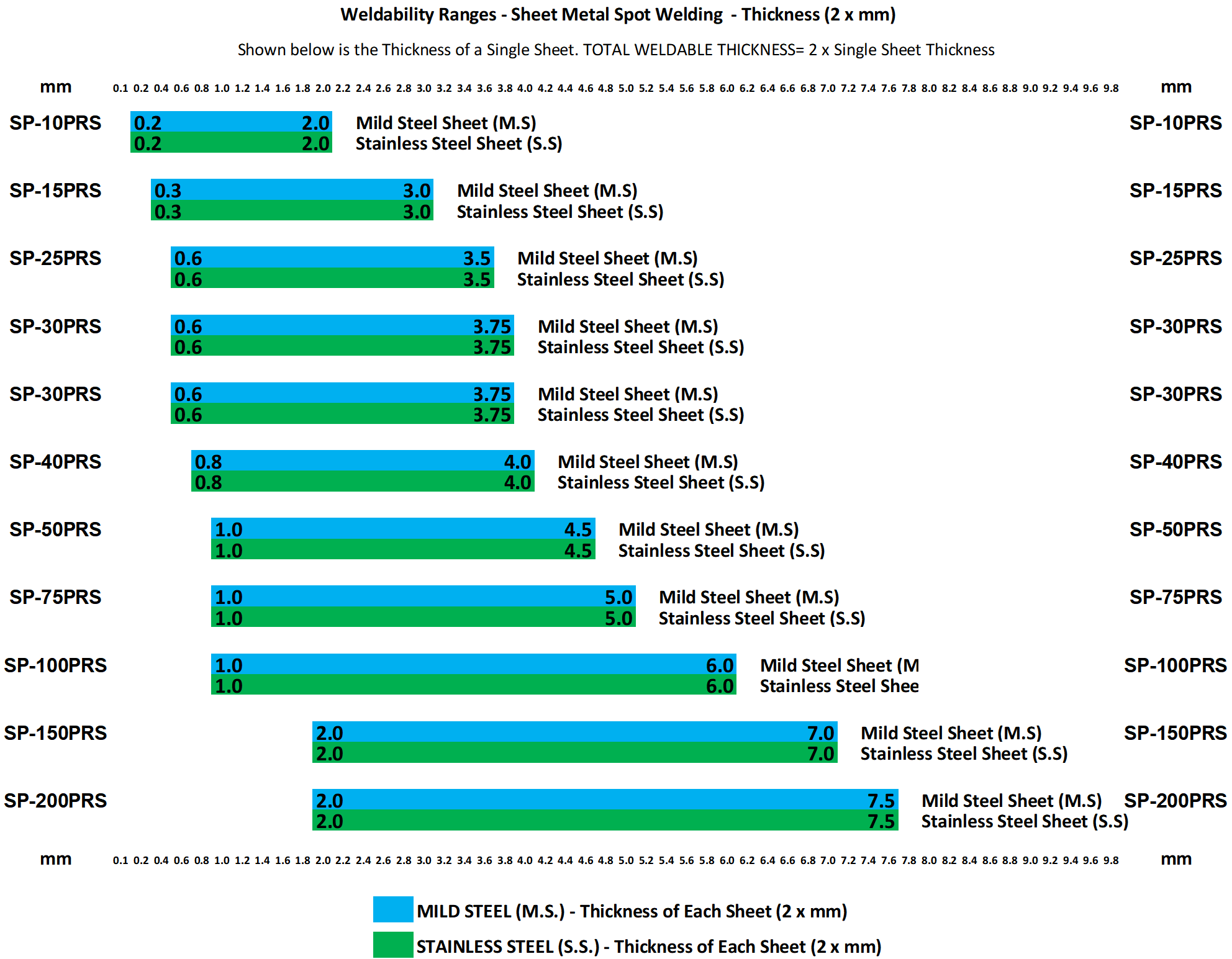

-(Weldability Sheet Thickness (2 x mm): S.S/M.S Sheet- 1.0mm-4.5mm, 7-19 SWG, 7-19 AWG)

-(Weldability Cross Wire/Mesh Application-Wire Diameter (2 x mm): 2.0mm-9.0mm, Approx. double the weldability ranges indicated above)

-(Weldability S.S/M.S Projection Weld Nut or Weld Bolt on S.S/M.S Sheet with Thickness-1mm-4mm(M): M8-M16)

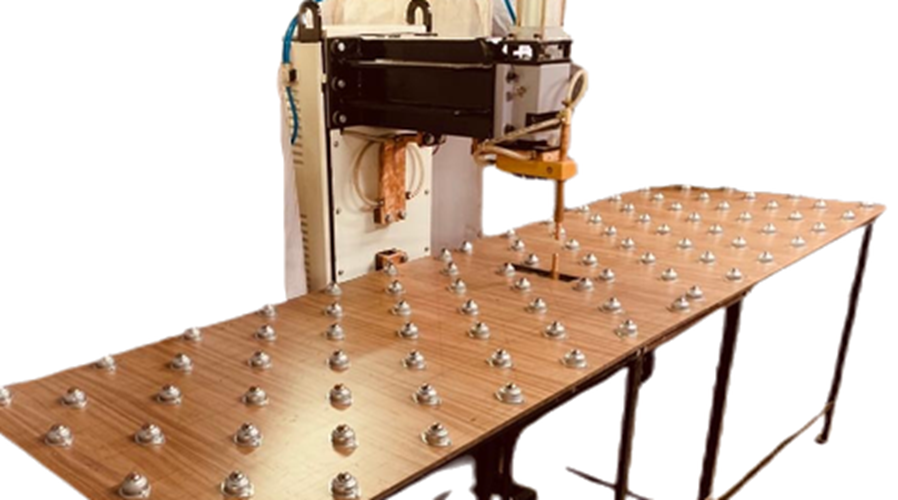

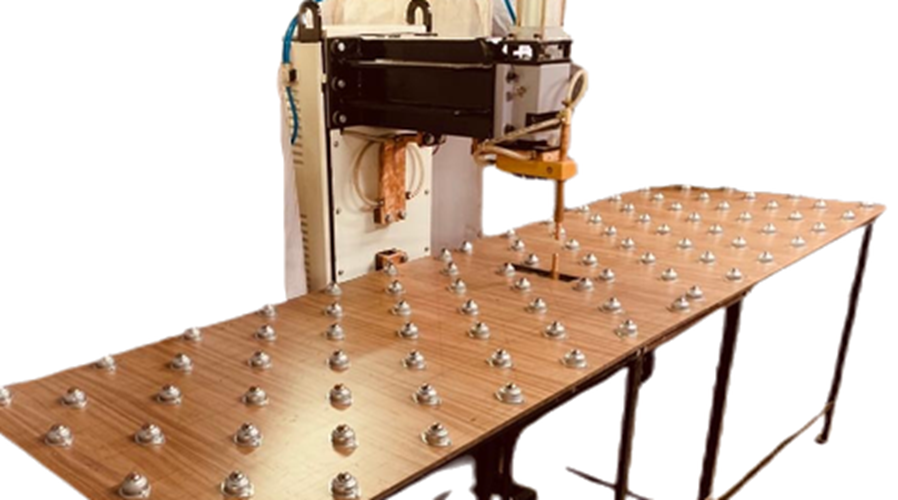

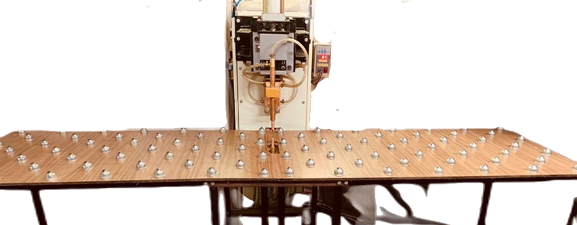

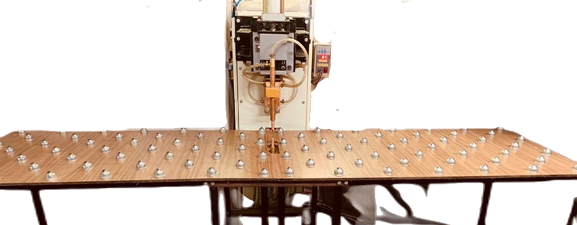

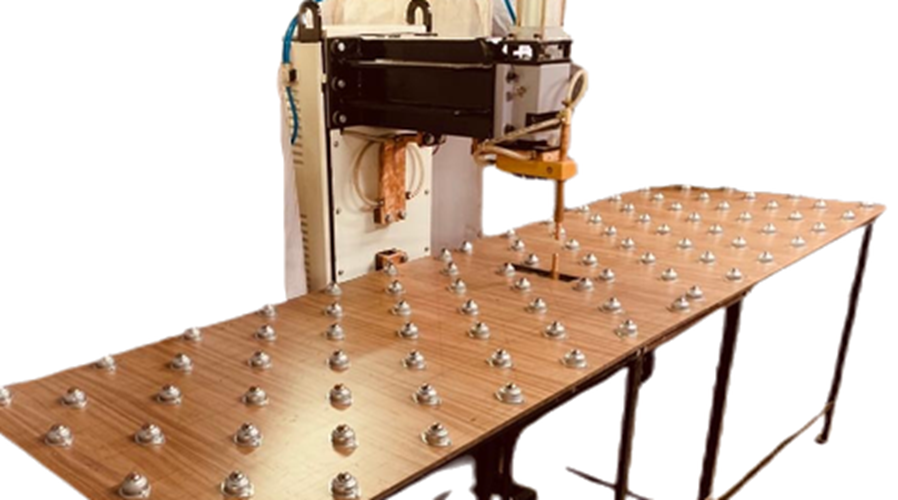

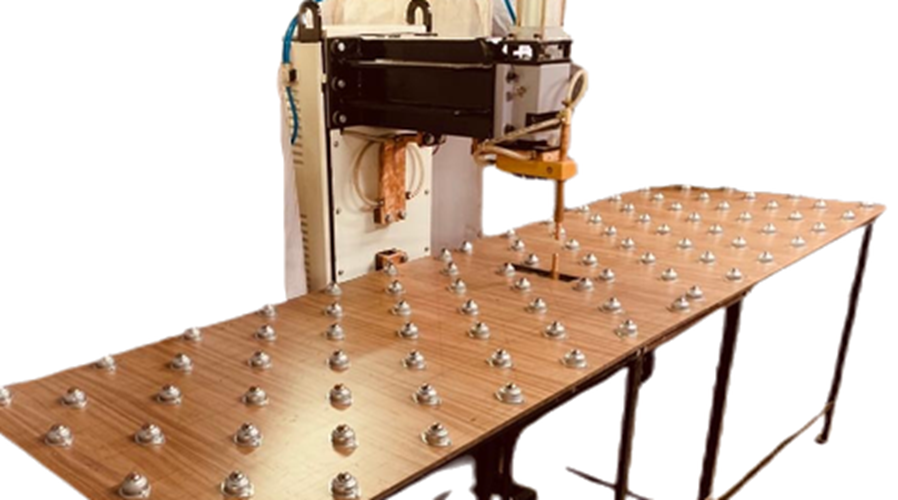

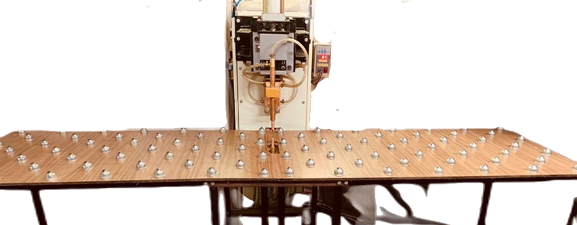

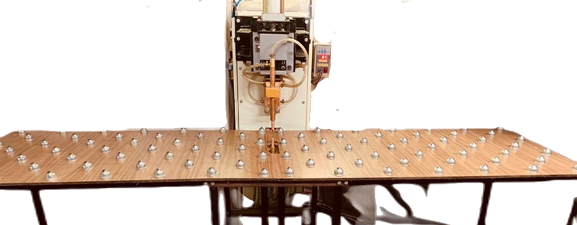

Applications: The Electroweld Elevator Door Spot Welding Machine is used to weld panels for Elevator Doors. The machine comes with a pair of tables equipped with roller balls for seamless movement of the Job and its placement at various points for the spots to be welded on the elevator doors. Capable of Welding Low Carbon Steel,High Carbon Steel,High Strength Steel,Nickel Alloy,High-Temp Alloy,Titanium.

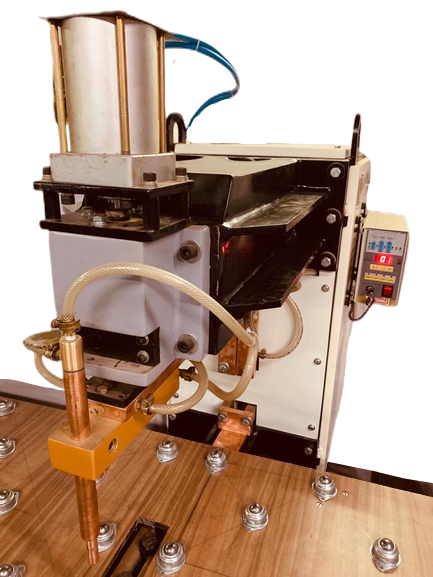

Operation: There one Press Type 50KVA Projection Spot welder provided as per the customer requirement. The operator loads the elevator door panels on the roller ball welding table and positions the job for the weld job. He then initiates the welding process via foot switch. The weld job is then moved to align with the next set of spots to be made. This sequence is repeated till all the spots are made.

Construction : Heavily fabricated with streamlined appearance, suitably stiffened at points of stress. The transformer is mounted directly on to the body and the bearings for the arm are provided in the same.

Cooling System: Electrodes, Electrode holders secondary water cooled, water required to be free from residue forming impurities and at a temperature of less than 30* C or 85* F. If water temperature is higher, increased water flow is required.

Electrodes: Two pair Morse Taper II straight electrodes supplied as standard with the machine, Other types available on request.

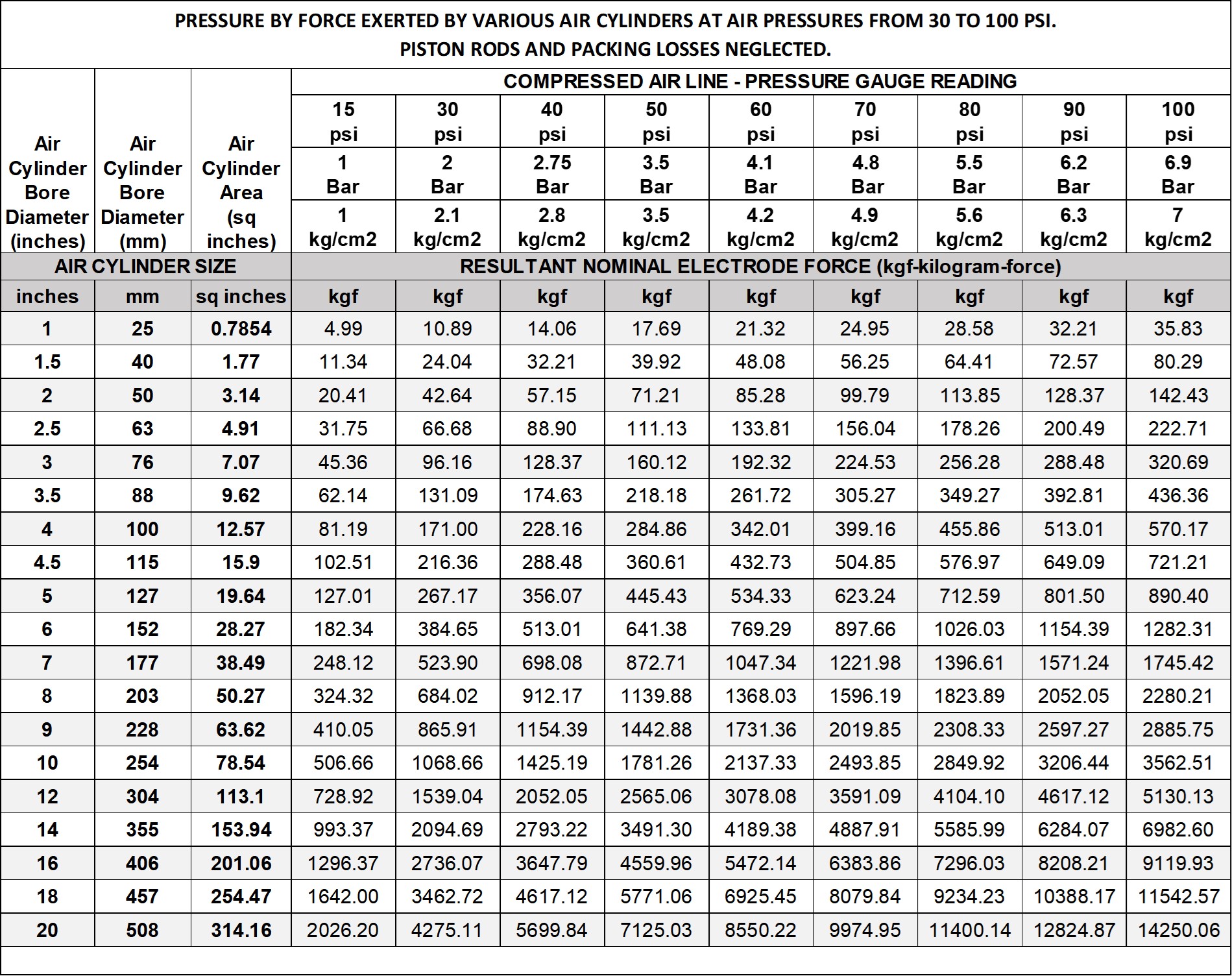

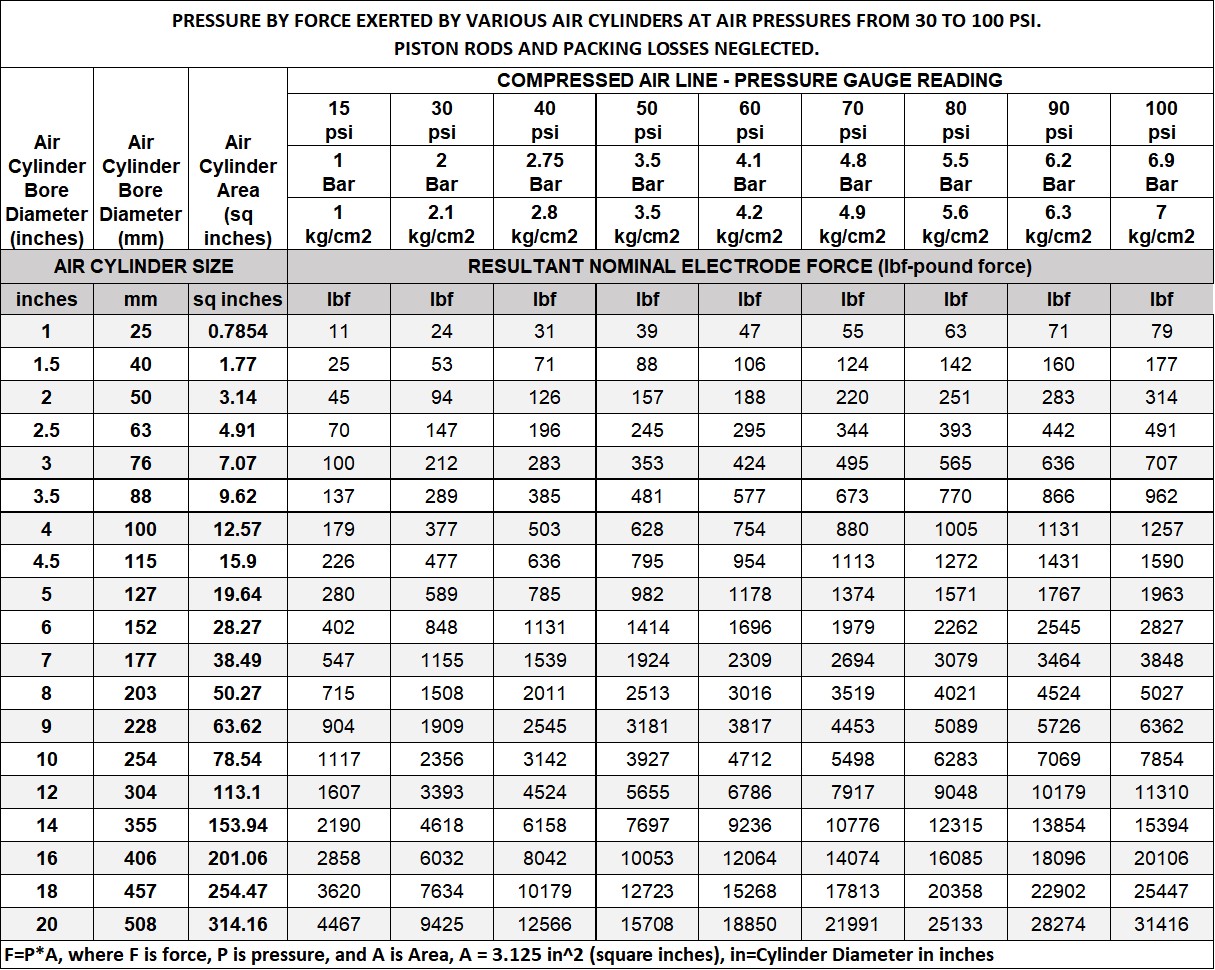

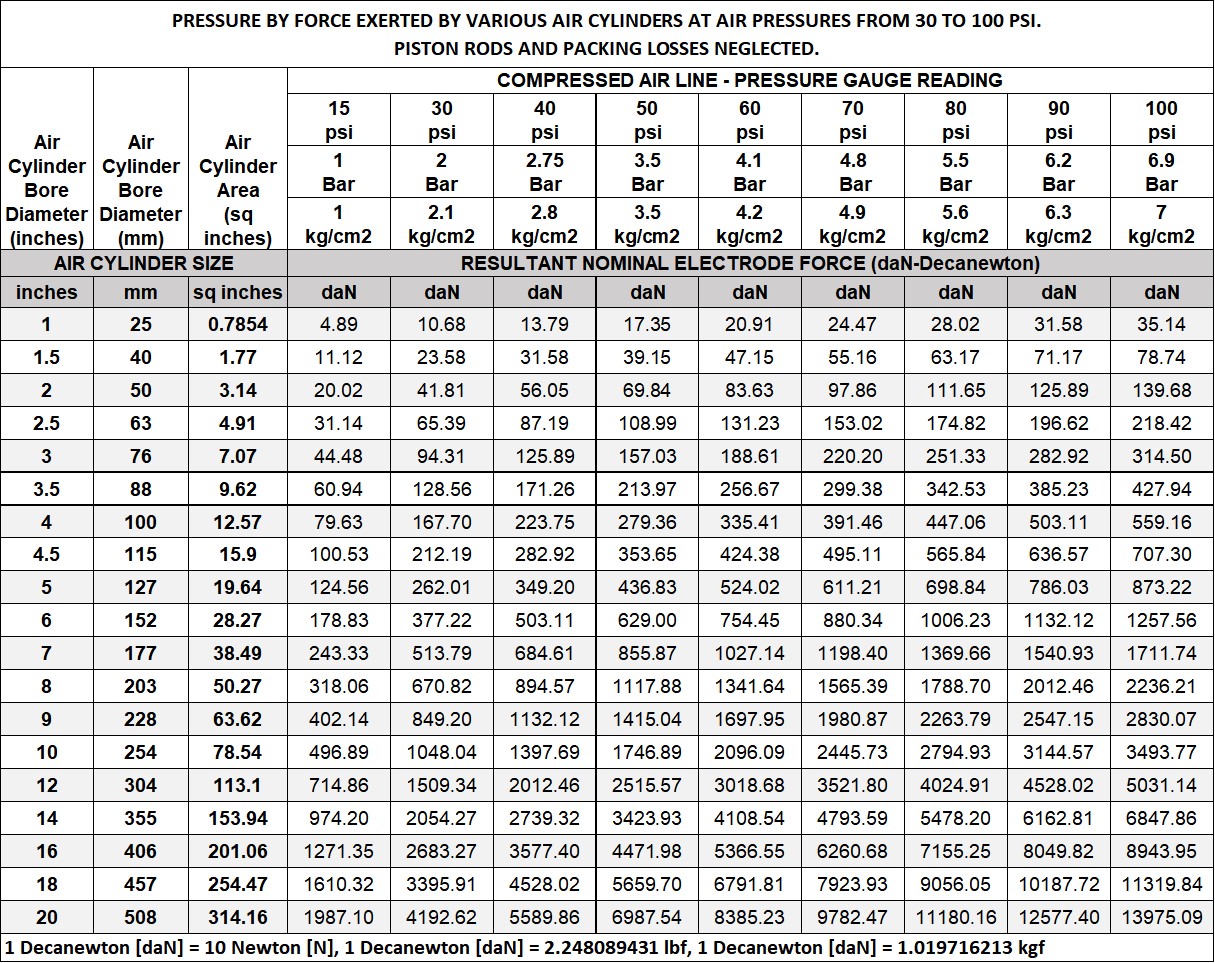

Adjustment of Electrode Force : By means of Air Pressure. The force is adjustable and gives a constant force from 1-5 Kg Cm!by Pneumatic Cylinder, adjusted by Regulating Valve.

Adjustment of Electrode Stroke: By vertical adjustment of electrode holder.

Current Control: By means of 3/6 tap change links between 50% and 100% also fine setting through controller

Weld Initiation: By means of Foot Switch which initiates the weld only after preset pressure is built up.

Electronic Control:

(A) Thyristorised synchronous electronic sequence timer consisting of: Squeeze, weld, forge, off and heat control unit range 1-99 c/s. This is a standard controller offering.

(B) Solid State - three timers provided for squeeze, weld and forge timings - short range 5 - 50 cycles - long range 1 - 10 seconds (50 to 500 cycles). This is a standard controller offering.

(C) Optional Electroweld AY-01 Digital Timer with capability to store upto 25 different weld schedules. This option will replace the standard controller at an additional cost.

(D) Optional Forwel AK-54V Constant Current Digital Controller with capability to store and recall upto 15 different weld schedules (additional cost). This option will replace the standard controller at an additional cost.

Electroweld Press Type Projection/Spot Welder 50KVA @ 50% Duty Cycle (SPM-50PRE)

-(Weldability Sheet Thickness (2 x mm): S.S/M.S Sheet- 1.0mm-4.5mm, 7-19 SWG, 7-19 AWG)

-(Weldability Cross Wire/Mesh Application-Wire Diameter (2 x mm): 2.0mm-9.0mm, Approx. double the weldability ranges indicated above)

-(Weldability S.S/M.S Projection Weld Nut or Weld Bolt on S.S/M.S Sheet with Thickness-1mm-4mm(M): M8-M16)

*Weldable Materials-Low Carbon Steel,High Carbon Steel,High Strength Steel,Nickel Alloy,High-Temp Alloy,Titanium,Bronze,Brass

Note: For Bronze and Brass the Weldable thickness reduces and specs are available in table below

* Galvanized Steel Sheet Spot Welding- Galvanizing is a coating of zinc metal that is applied to the steel when it is manufactured, either in a hot dipped fashion or by electroplating. Zinc, when used as a galvanizing coating, protects steel from rust. Galvanized steel requires about 25% more horse power than non-galvanized steel. Weld time and/or weld power need to be increased to spot weld Galvanized steel. Select a higher KVA machine to account for the increased power requirement for spot welding Galvanized steel.

* Power Requirement is 415V AC 50/60Hz(Price includes customization as per requirement before shipping)

**Spot Welders upto 30KVA can operate on either 2 Lines/Phases 220V (+10%/-10%) or 400V (+10%/-10%) 50/60Hz

***Spot Welders greater than 30KVA can only operate on 2 Lines/Phases 400V (+10%/-10%) 50/60Hz

** Standard Throat Depth is 18" or 460mm (Customizable to 12” / 18” / 24” / 30” / 36” / 48” / 60” / 72” at an additional charge)

***Standard Electroweld Micro Processor Controller with 3 timers for squeeze, weld & forge timing

***INCLUDED Standard Coolant Re-circulator Water Pump which is required for proper operation. Specs - 220V/415V 1/3 Ph 220V/440V

****Additional set of spares and consumables can be quoted to be added to the shipment as required

****In case of a similar machines customized with multiple Weld-Heads, we can also integrate separate transformers and timer controls for each Weld-Head at an additional cost. This will enable capability to weld 2 parts with different weld setups simultaneously. Save time and effort by finishing the job simultaneously. No more queueing parts, staging, or running the same part on two different welders. Additionally the multiple transformer-multiple weld head strategy could also be used to optimize utilization of existing power capacity available at your factory whereas a higher KVA machine doing the same set of simultaneous welds could require a new higher capacity power connection.

****The following specifications Table is for Single Head Welders with a single transformer. It is only provided here as a reference. With multiple heads, the rating of the machine and weldability varies depending on the number of transformers integrated in the machine and the number of welding heads used simultaneously in the weld sequence. Please contact us for weld specifications customized to your application.

*****For example a 50 KVA Press Type Projection/Spot Welding Machine with 2 Welding Heads would result in each Welding Head having the welding capacity equivalent to a 25 KVA Machine. Similarly in order to size the transformer for a Multiple Head Projection/Spot Welding Machine, we need to take the base KVA rating of a single head machine capable of welding the required part and multiply that KVA rating with the number of Welding Heads to come up with a composite KVA rating for the Multiple Head Projection/Spot Welding Machine.

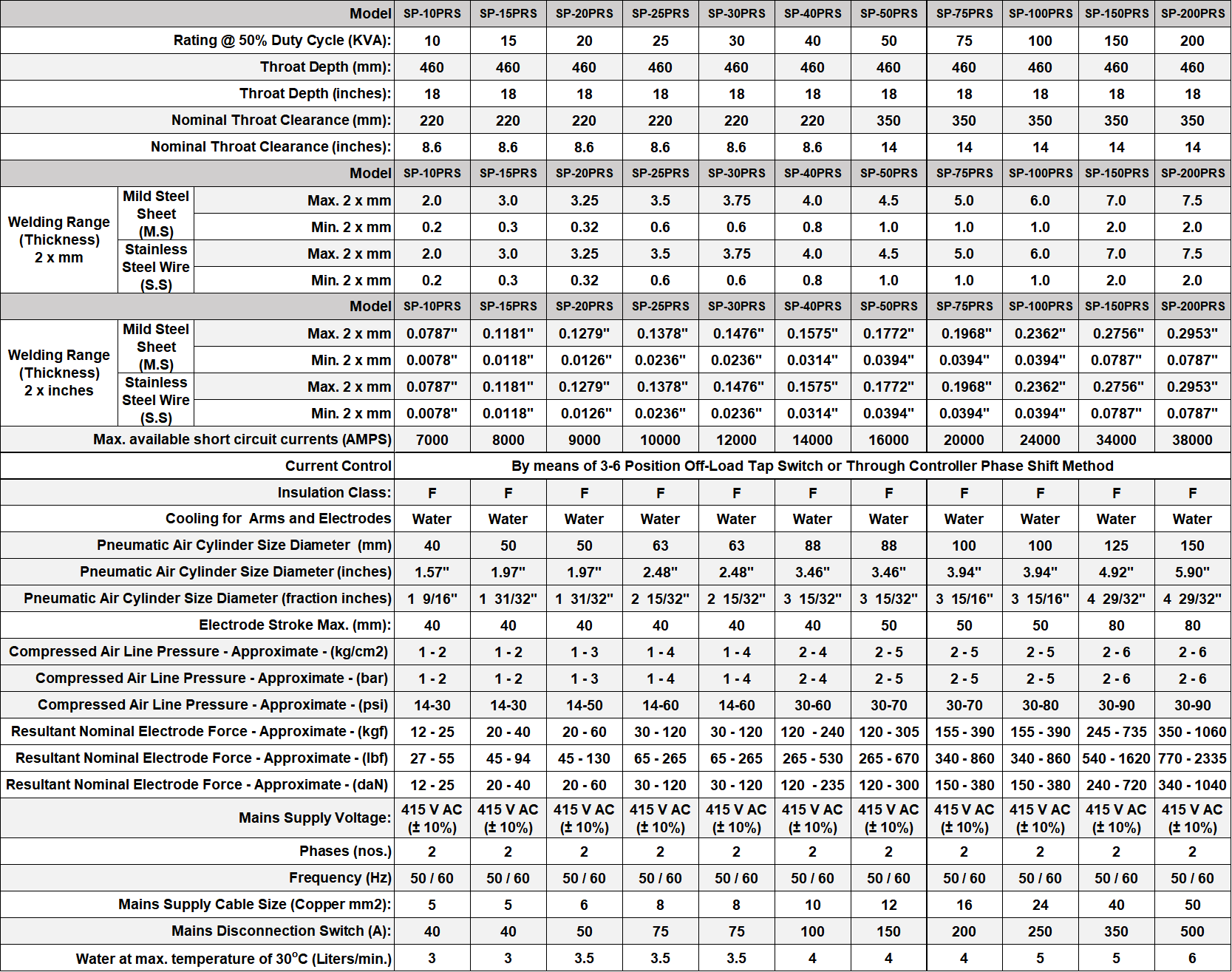

Specifications Table - Sheet Metal Spot Welding Application:

Note: * Maximum material welding thicknesses are always estimates. Variables such as Electrode Throat Depth, Electrode Throat Clearance, tooling, shunt or cable length, welder distance from primary, and other compounding variables can positively or negatively affect this number.

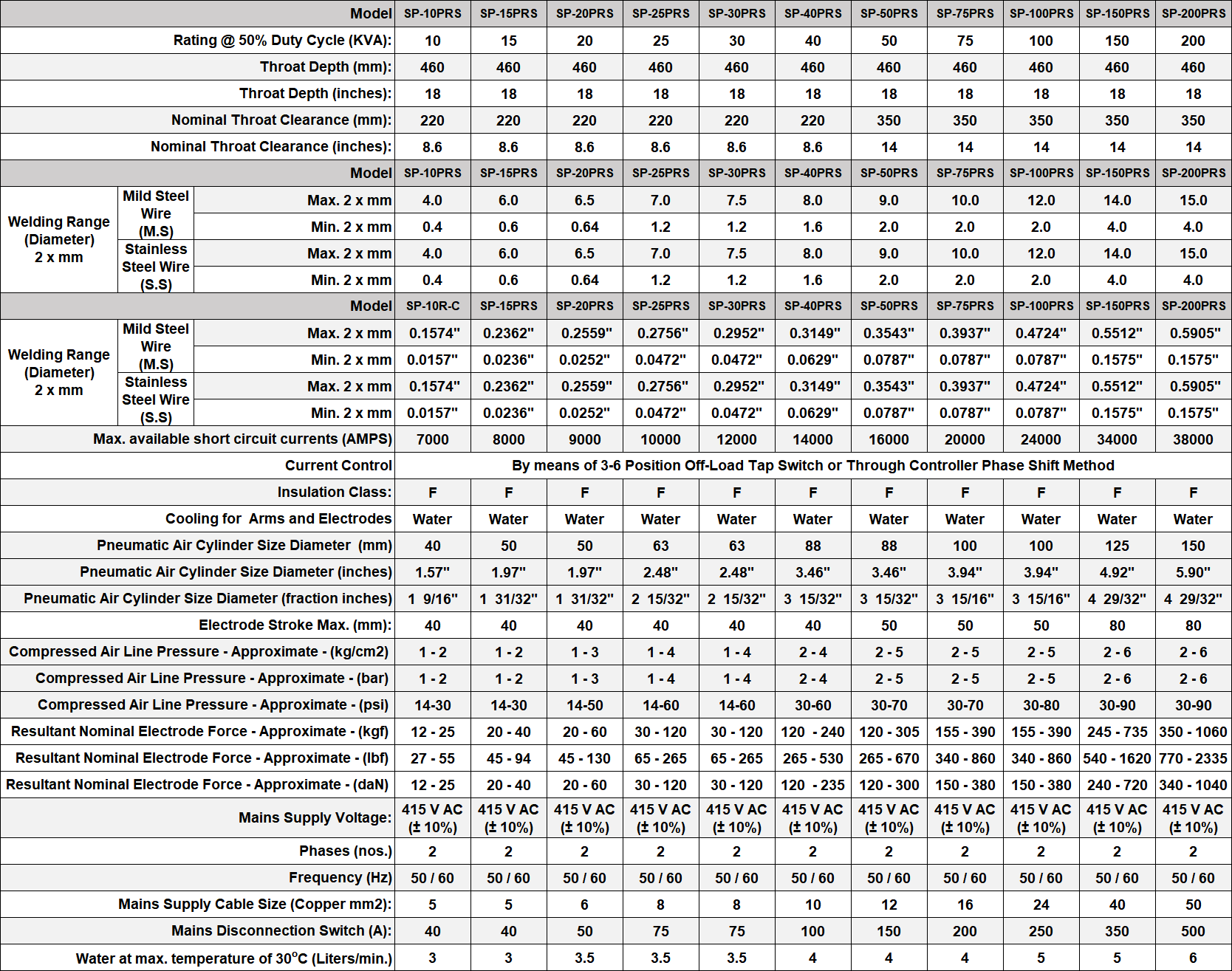

Specifications Table - Cross Wire or Mesh Spot Welding Application:

Note: * Maximum material welding thicknesses are always estimates. Variables such as Electrode Throat Depth, Electrode Throat Clearance, tooling, shunt or cable length, welder distance from primary, and other compounding variables can positively or negatively affect this number.

The weldability of your application can be checked with the Electroweld KVA-mm-SWG-AWG Mapping Table for MS/SS available HERE

The Electroweld Projection Spot Welder Weldability Table with SWG-mm-KVA Mapping is available HERE

The Electroweld Projection Spot Welder Weldability Table with AWG-mm-KVA Mapping is available HERE

![LG 55UR80006LJ 140 cm (55 Zoll) UHD Fernseher (Active HDR, 60 Hz, Smart TV) [Modelljahr 2023]](https://cdn.shopify.com/s/files/1/0479/6992/7335/files/91RDtCRss5L.jpg?v=1730136243)